2025 CFSEI DESIGN EXCELLENCE AWARD WINNER

THIRD PLACE - MUNICIPAL

LOCHSA ENGINEERING, LLC – LA CHARGERS HQ & TRAINING FACILITY – “THE BOLT”

EL SEGUNDO, CALIFORNIA

LA Chargers HQ & Training Facility – “The Bolt” LA Chargers HQ & Training Facility – “The Bolt”

One Chargers Way

El Segundo, California 90245

Completion Date: July 2024

Construction Cost: $250 Million

Owner: Los Angeles Chargers.

Architect of Record: Steve Chen Chung, Gensler.

Engineer of Record for Structural Work: Whitney Lee, Walter P Moore and Associates, Inc.

Cold-Formed Steel Specialty Engineer:Derrick Suarez, P.E., Lochsa Engineering , LLC.

Cold-Formed Steel Specialty Contractor: Kiley Hough, Component West.

Award Entry Submitted by: Nick Hrico, P.E., Lochsa Engineering, LLC.

Project Background

The Bolt is the first dedicated NFL team training facility and headquarters constructed in Los Angeles. Featuring a striking interior and exterior design that reflects the spirit of the Chargers, the facility takes its name from the team’s iconic lightning bolt logo—symbolizing innovation, energy and agility. Spanning 150,000 square feet across a thoughtfully planned three-level layout on 14 acres, The Bolt houses three full-size natural grass practice fields and supports a wide range of essential team functions, including athletic training, medical support, team meetings and player amenities—all aimed at enhancing performance and promoting collaboration.

The ground floor includes dedicated training and medical spaces, a spacious locker room and an equipment room, along with player-focused amenities such as lounges, hydrotherapy and recovery rooms, a sauna, steam room, barber area and an outdoor lounge. The second-floor features meeting rooms, a turf walk-through space on the balcony and a two-story team meeting room. Culinary services are led by Wolfgang Puck Catering and include a tile mosaic Chargers’ helmet-inspired pizza oven. The top floor offers a private, members-only club with a wrap-around outdoor balcony, lounge, dining space and private dining room. This level also includes executive and staff offices, conference rooms and content creation hubs.

The Bolt is a premier space for professional sports and entertainment. Its exceptional design and cutting-edge technology make it a versatile venue for events—reinforcing its role as a central hub for both the Chargers and the greater Los Angeles community.

Design Challenges and Solutions

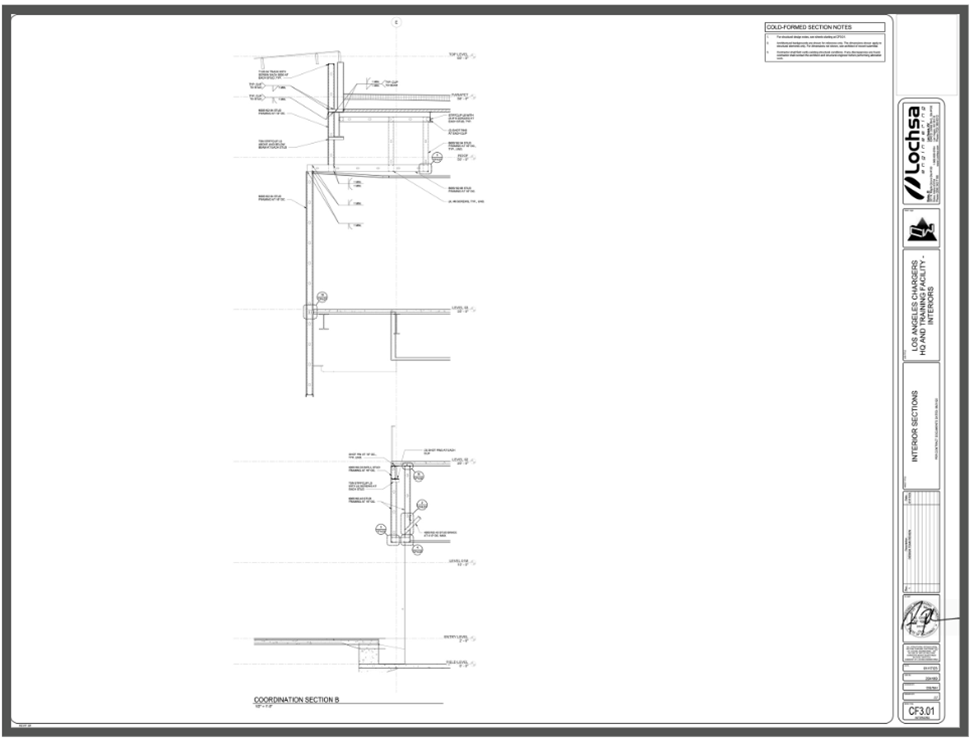

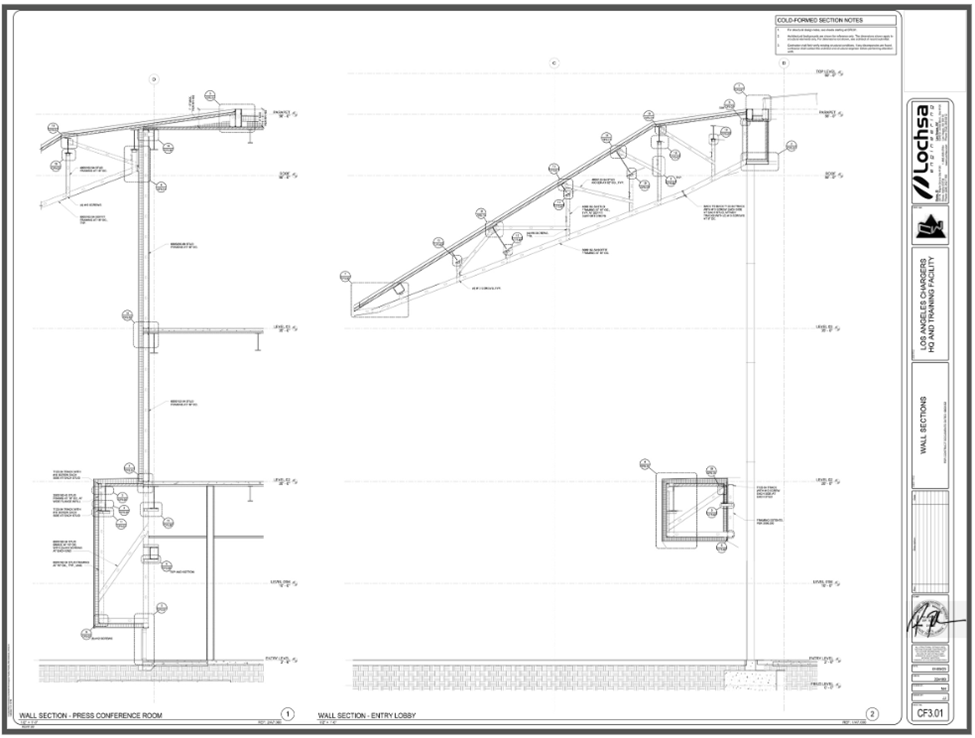

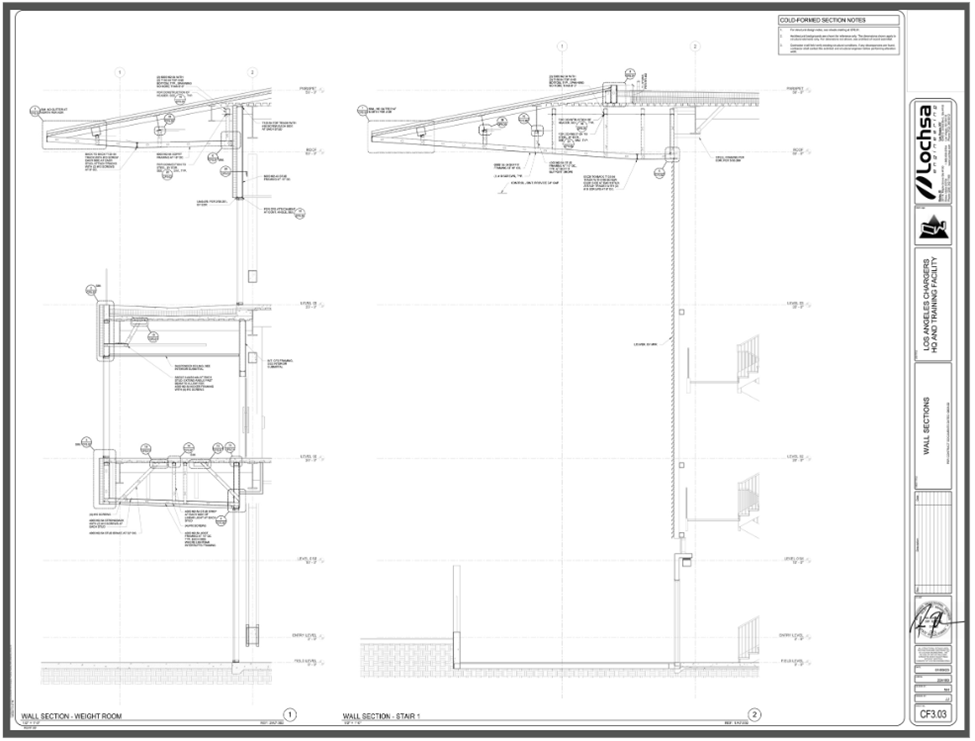

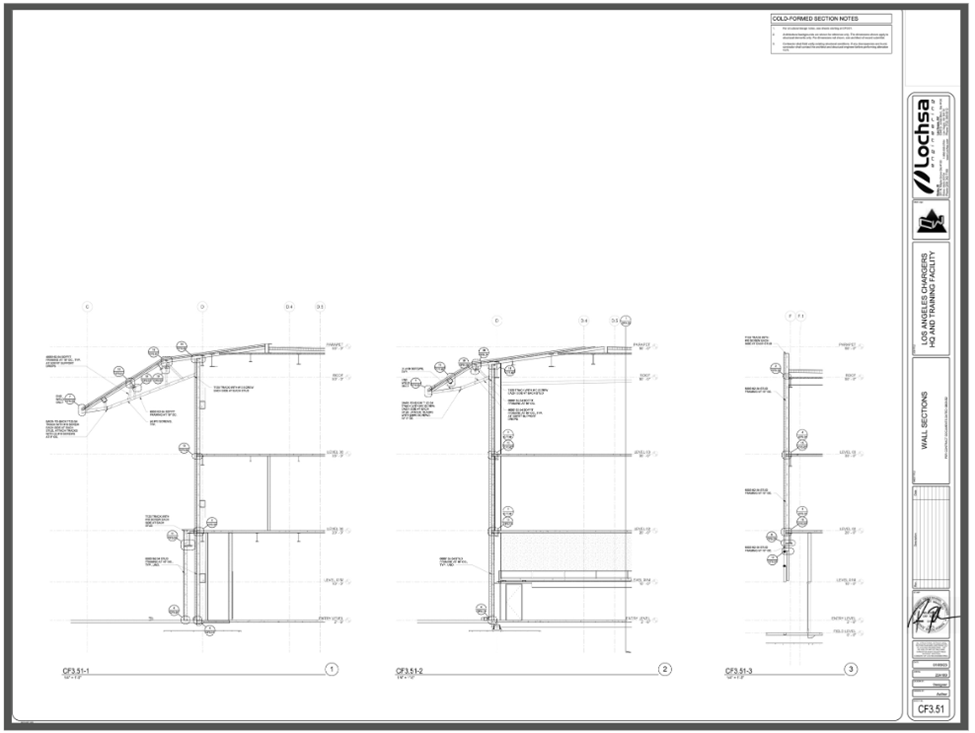

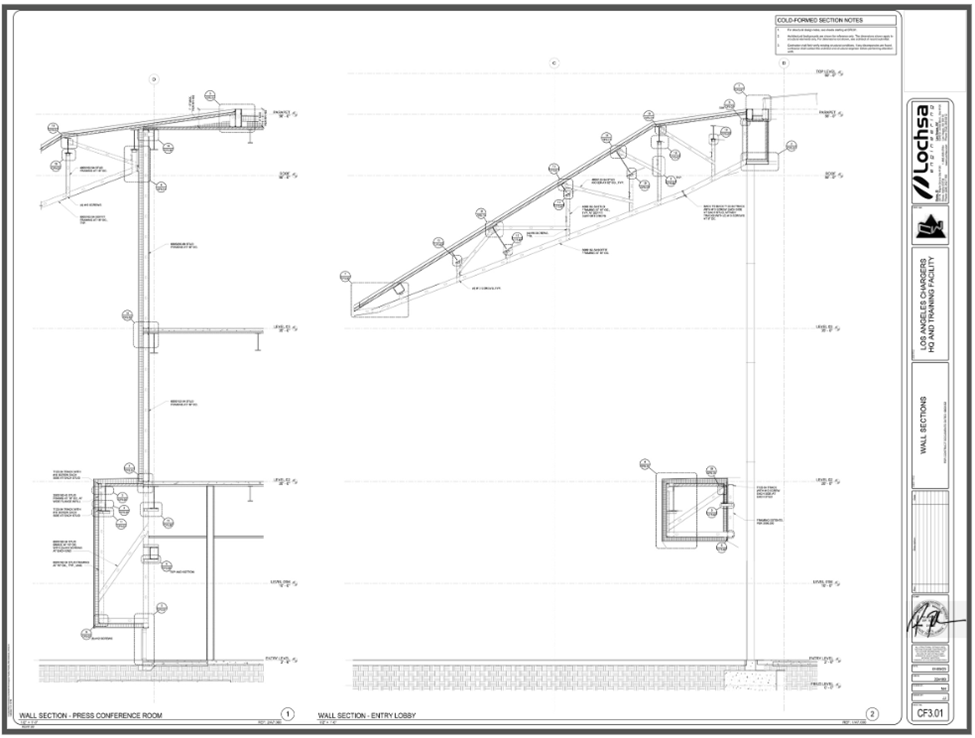

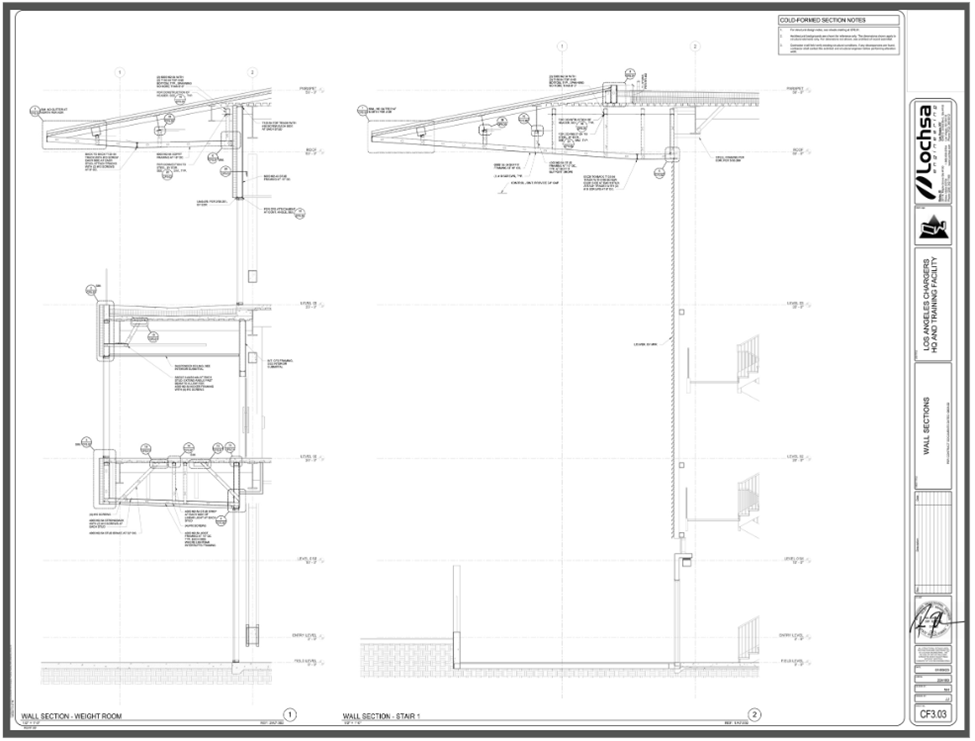

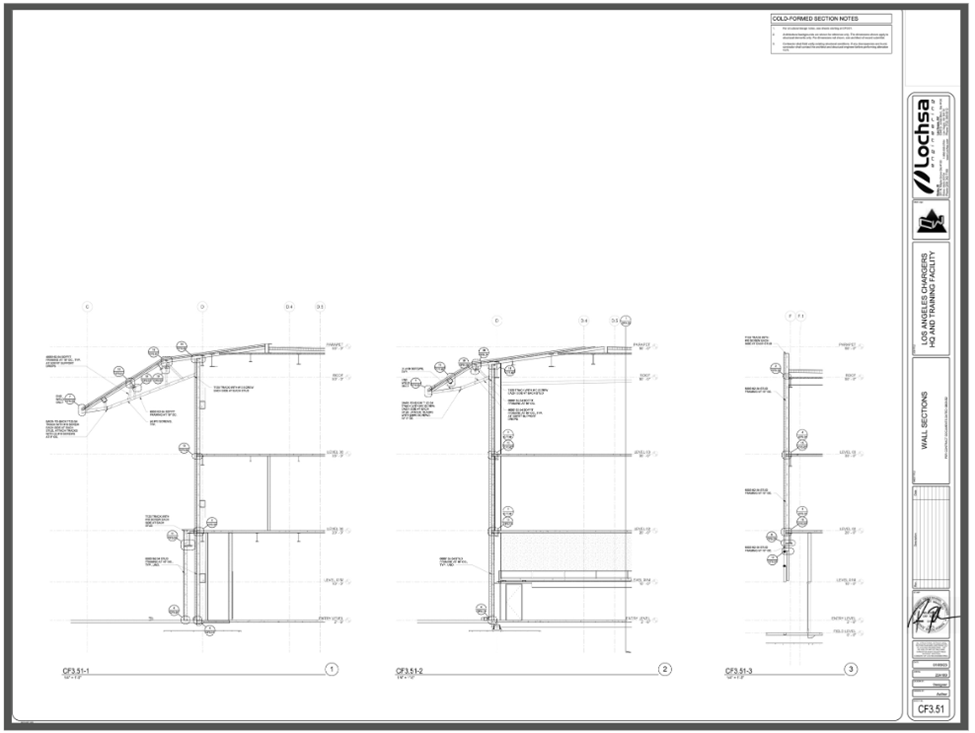

Front Entrance Wall with Integrated “Bolt Peak” and Overhang: The intricate cold-formed steel (CFS) front entrance wall tapers vertically in two individual planes while being adequately connected to the base structure framing. The complexity of the design and detailing for vertical/horizontal code loads and building drift compliance had to be accounted for at three distinct bearing elevations along the building elevation.

Integrated within these wall planes is the Bolt Peak, which protrudes at a consistent linear elevation at the top while the bottom portion tapers to a point independent of the tapering walls behind. To create this element, CFS framing members were connected to the base steel (i.e., red iron) structure, using a system of vertical, diagonal and cantilevered CF members and connections. Strict attention to detail, and the use of a building information model (BIM) in conjunction with structural engineering design software (i.e. Ram Elements), assisted in efficiently laying out the CFS framing grid with the typical architectural elevations while accounting for the MEP construction trade elements to create a solid, seamless, entry wall finish.

The CFS framing system for the large overhang feature required thoroughness with structural engineering design and detailing. The completed CFS assembly was integrated into the main building steel (i.e. red iron) with tapering/angling members and connections out of a 90-degree layout while still addressing the large wind uplift/suction forces.

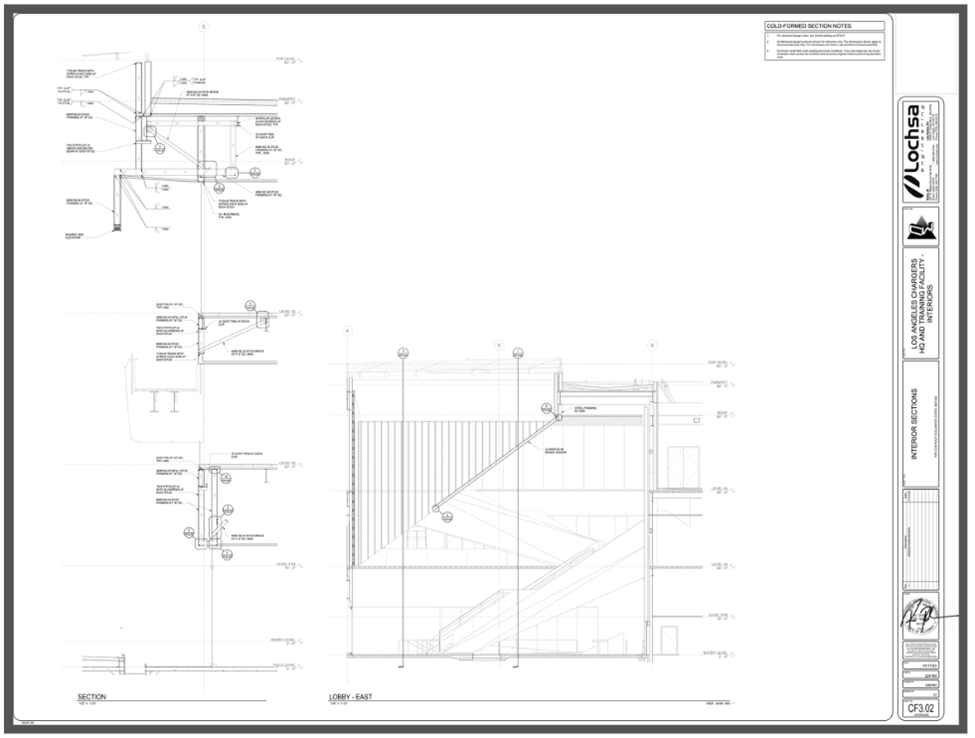

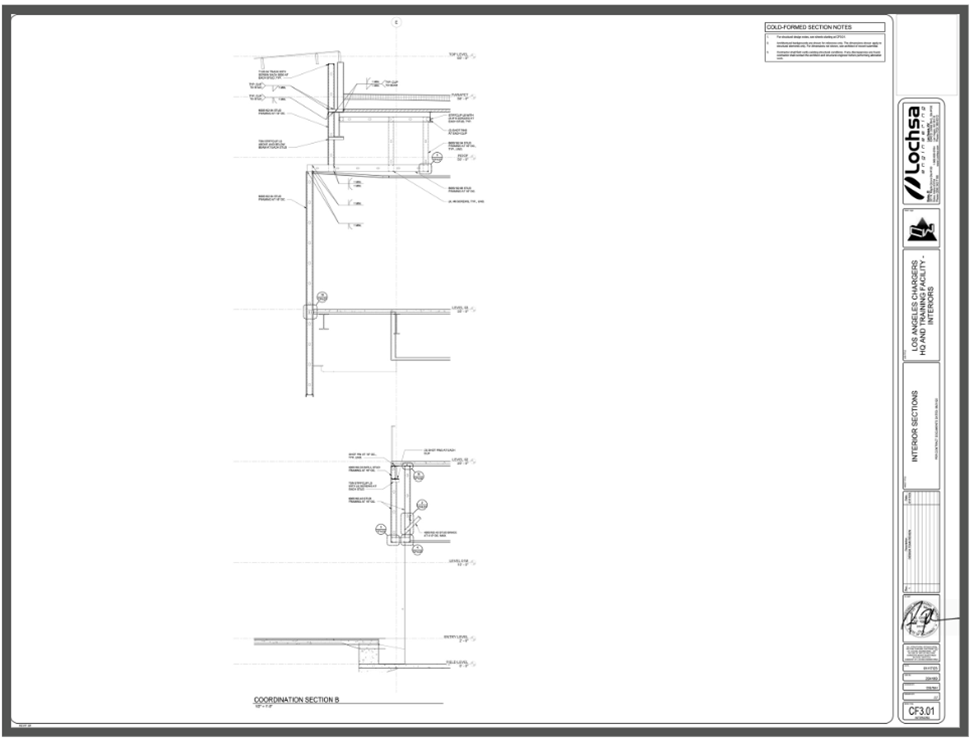

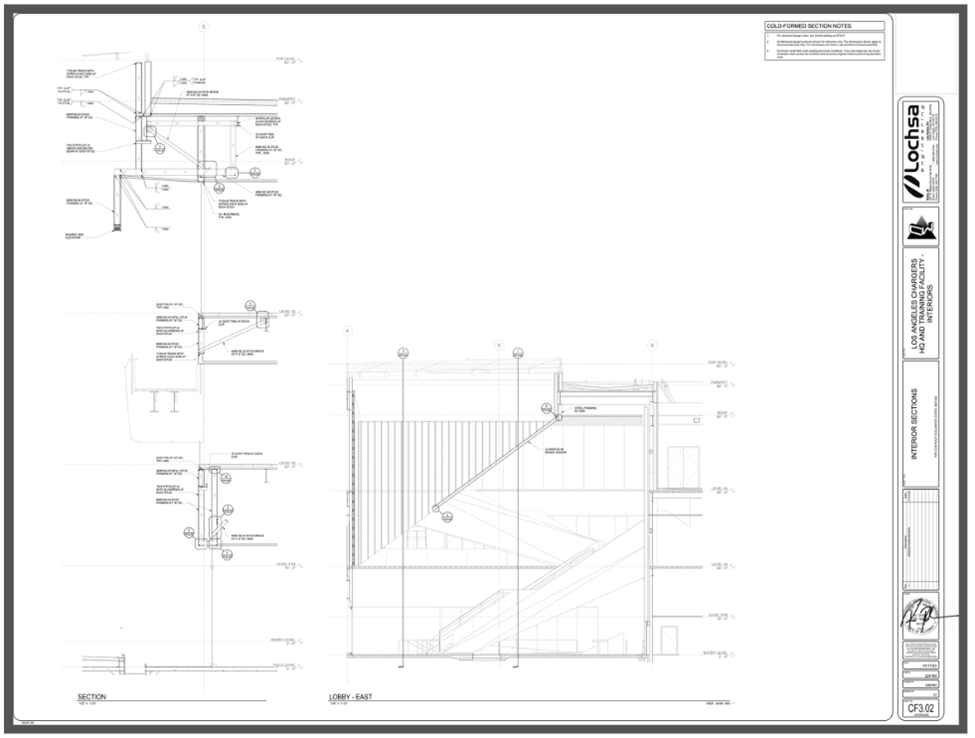

Interior Main Entry Lobby Walls with LED Board: Designing the wall system here was an immense challenge. All walls and related systems had to incorporate the look of a lightning bolt and it’s sharp lines. The CFS framing support and connections for the geometric vertical, sloped and horizontal planes were a complex undertaking, but essential to achieving the architectural look and feel needed to make a lasting visual impression upon entering the facility. All support framing members and connections had to remain discreet, with little to no visual impact on the finished product.

The structural design challenges were compounded by key architectural elements occupying the space, including the main stair with intermediate landing, a large LED board and a skylight, which all had to be of integrated precisely into the wall layout.

The project stakeholders coordinated details to ensure support for the framing, which remained out of sight to occupants. This high level of detailing was made possible by leveraging the BIM and structural engineering design software to align the CFS framing grid with the architectural elevations. The resulting detailing exceeded what is typically included in standard CFS shop drawings, which included multiple elevations and sections to illustrate the framing layout. Custom details were included beyond the standard CFS package. The CFS framing system also met all current code design loads and deflection/building drift criteria, since the project site is in a high seismic zone.

|

|

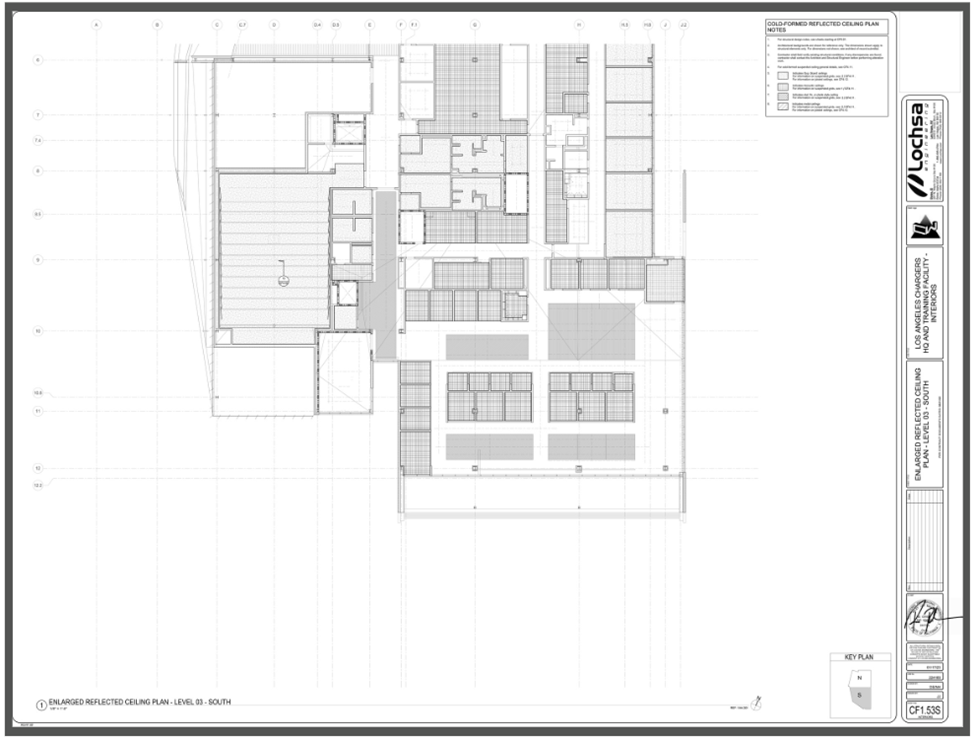

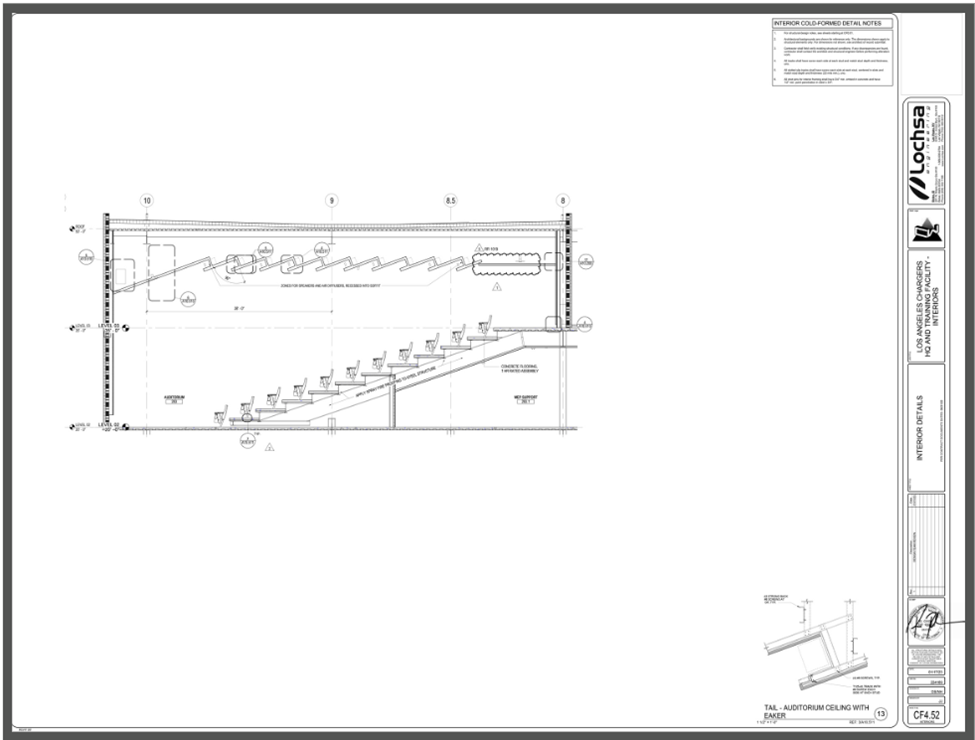

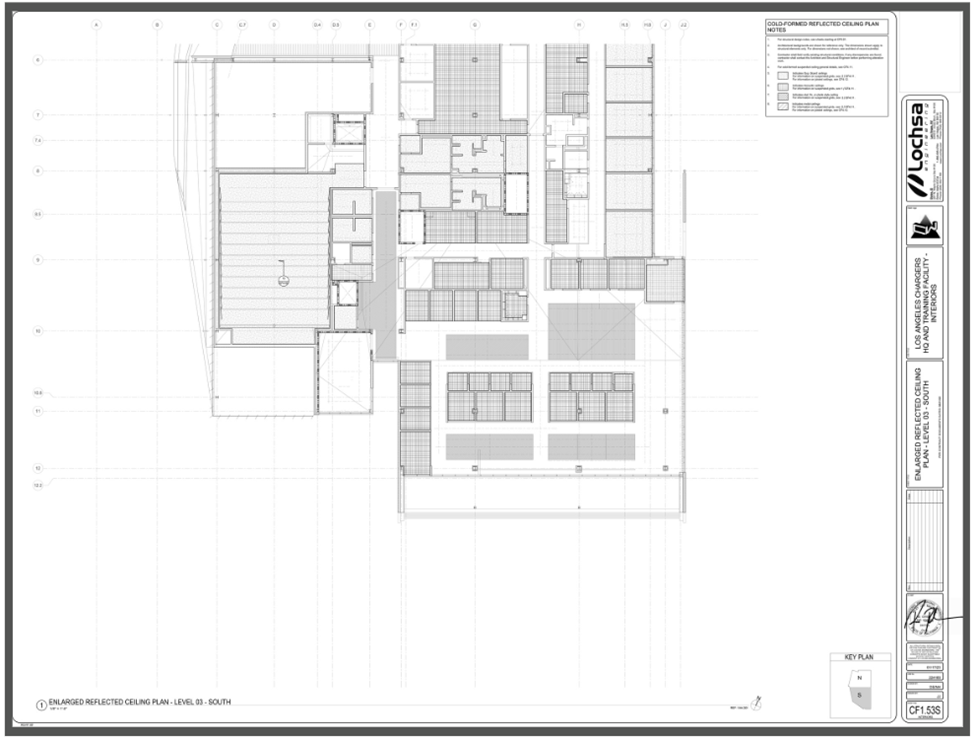

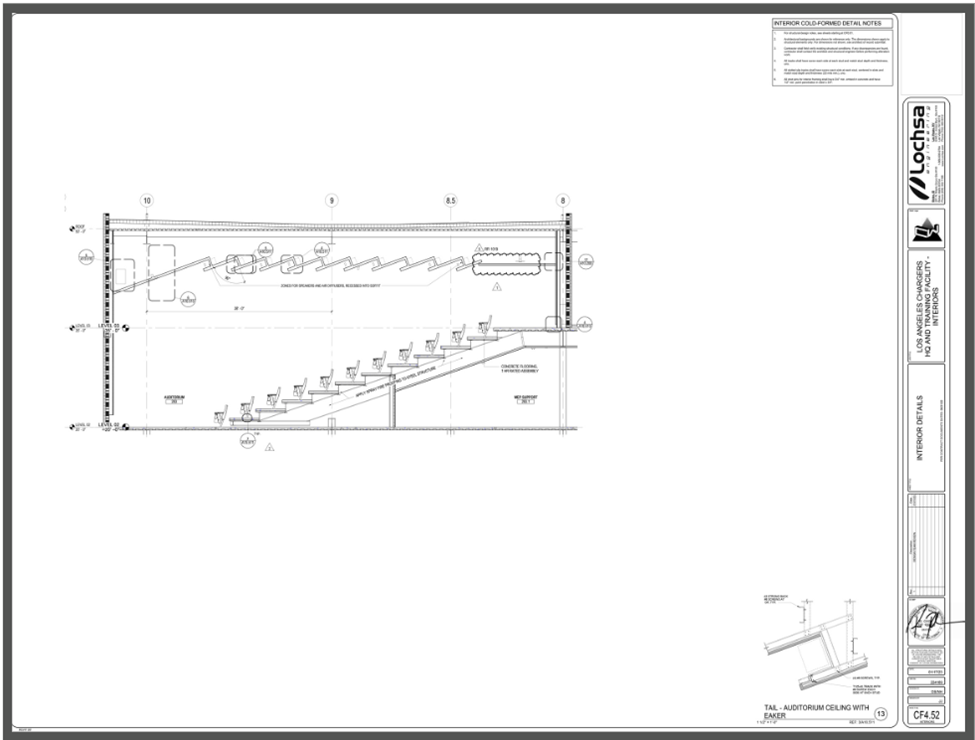

Team Auditorium/Meeting Room Ceiling System: This dynamic space was a major focal point to the team ownership, coaches and players in the facility. The intended use is for important team meetings throughout the year. The visual feel of the environment was to reflect the team’s lightning bolt theme used throughout the building.

The final ceiling layout immolated this with undulating vertical and horizontal planes throughout the envelope of the space. CFS framing members and connections were the best materials to create this appearance. This ceiling pattern required vertical, angled and horizontal support members hidden within the meeting room “lid,” while also accounting for recessed speaker and air diffuser systems.

Conclusion

Along with strict architectural guidelines for each design challenge, the CFS framing system needed to address all the current code design loads and deflection/building drift criteria as the building site is in an extremely high seismic zone.

All these design challenges were able to be achieved by applying the versatility of CFS framing members/connections and the ability to create intricate framing grids with non-standard connection scenarios that are properly designed with methodologies that pertain to proper engineering design and detailing. This is achieved by having experience in the industry, a knowledgeable construction/design team and continued education by involvement in industry support groups such as the Cold Formed Steel Institute e.tc.

This remarkable project, skillfully executed by Lochsa Engineering, not only showcases the firm’s technical expertise, but also reinforces its leadership in the engineering community.

|