FAQ OF THE MONTH

JANUARY 2026

QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing requires a 0.35 reduction be applied for gypsum sheathed shear walls without blocking. It then requires all horizontal applied sheathing be panel blocked. We have engineers interpret this differently. Some will say all gypsum shear walls must be panel blocked and the 0.35 is for panels not having solid wall blocking. Others interpret this as allowing no panel blocking if you hit the capacity by 0.35. Can you help clarify how these two requirements relate and/or where this 0.35 comes from so we can put this to bed? QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing requires a 0.35 reduction be applied for gypsum sheathed shear walls without blocking. It then requires all horizontal applied sheathing be panel blocked. We have engineers interpret this differently. Some will say all gypsum shear walls must be panel blocked and the 0.35 is for panels not having solid wall blocking. Others interpret this as allowing no panel blocking if you hit the capacity by 0.35. Can you help clarify how these two requirements relate and/or where this 0.35 comes from so we can put this to bed?

ANSWER: The following is proposed language to be added to the SFIA AISI S240, North American Standard for Cold-Formed Steel Structural Framing, 2026 Edition ANSWER: The following is proposed language to be added to the SFIA AISI S240, North American Standard for Cold-Formed Steel Structural Framing, 2026 Edition

B5.2.2.2.3.4 Gypsum Board Panel Sheathing

Section B5.2.2.3.4 requires a 0.35 reduction factor be applied to all unblocked gypsum board shear wall assemblies (i.e. shear walls with no panel blocking). The panel blocking may be screw attached minimum 33-mil flat steel straps.

The blocking provides a load path between adjacent panels. The blocking functions similar for the diaphragms listed in Table B5.4.2.2-1 of this Standard and the SDI-AISI S310 side lap connection in profiled metal deck diaphragms. These standards enable one to design a diaphragm without consideration of side lap connections, but the diaphragm capacity is reduced. This is essentially what the 0.35 factor is doing for unblocked gypsum board shear walls.

The 0.35 factor is based on the tested performance of gypsum board shear wall assemblies.

DECEMBER 2025

QUESTION: I have a hanger rod attached to the flange of a roof framing joist. Is there a document where I can find max point load for such conditions? QUESTION: I have a hanger rod attached to the flange of a roof framing joist. Is there a document where I can find max point load for such conditions?

ANSWER: The connection design should consider the possible limit states of pull-over, pull-out and tension failure of the connector. These potential limit states are addressed by AISI S100. ANSWER: The connection design should consider the possible limit states of pull-over, pull-out and tension failure of the connector. These potential limit states are addressed by AISI S100.

The flange bending, however, requires engineering judgment. The bending of the flange theoretically may be evaluated using yield line theory. In the absence of a rigorous yield line evaluation, a design method based on the cantilever beam analogy may be employed.

Method No. 1

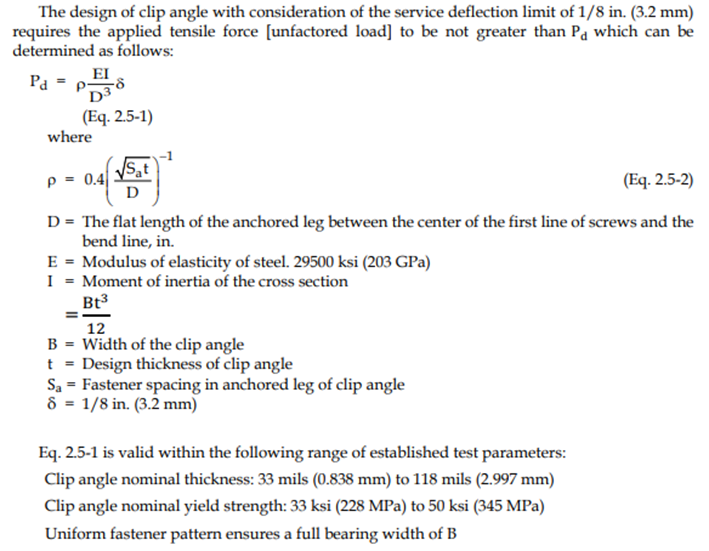

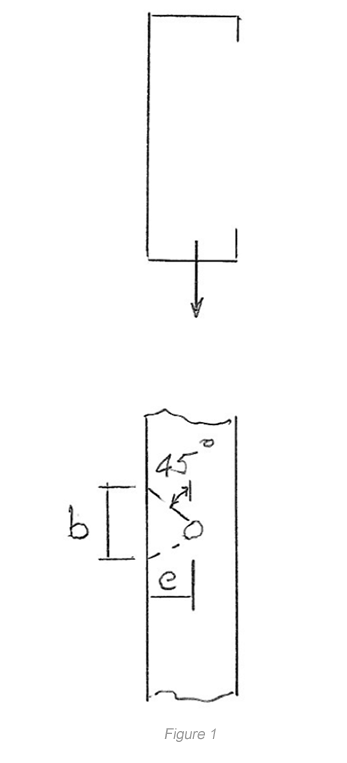

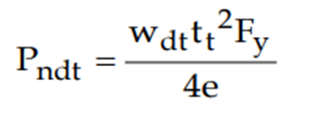

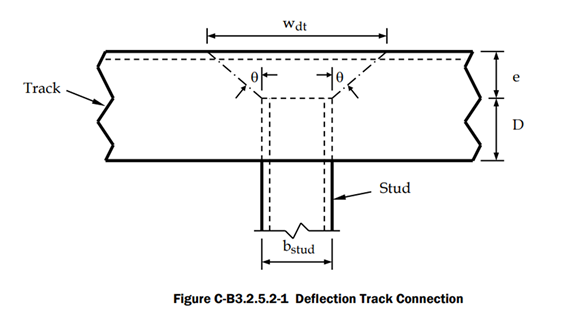

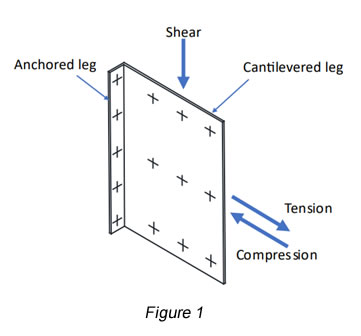

This method has been used in the metal building industry for hanging loads off of a purlin flange. The allowable load determined by using the cantilever beam analogy (Figure 1) assumes elastic behavior as follows:

Mn = SxFy = (bt2 /6) Fy

M = Pn e

Pn = (bt2 /6e) Fy

P = Pn/Ω

where e = distance from load application to the web centerline, b = 2e, Fy = yield stress, t = base steel thickness and Ω = 2.0 (AISI S100 Section A1.2).

However, one could assume the development of the plastic moment, thus using the plastic section modulus in lieu of the elastic modulus. Therefore, when using the plastic section modulus Sx = bt2/4.

Method No. 2

The provisions of AISI S240 Section B3.2.5.2.2, Deflection Track Connection for C-Section Studs, are based on a cantilever beam analogy. Thus, one may consider the use of Eq. B3.2.5.2.-1 to determine the load capacity of the flange.

NOVEMBER 2025

QUESTION: ASCE 7, Section 13.4.5 limits the use of power-actuated fasteners (PAF) in seismic design categories D, E, and F for nonstructural components. The reduction includes a maximum design load per fastener of 90 lbs. into concrete and 250 lbs. into structural steel. Some of our projects are in seismic design categories D, E, and F but the seismic design force does not always govern when checking against wind. In cases where seismic design force does not govern, are we allowed to use full capacity of these PAF fasteners regardless of the connection type for other loading applications? QUESTION: ASCE 7, Section 13.4.5 limits the use of power-actuated fasteners (PAF) in seismic design categories D, E, and F for nonstructural components. The reduction includes a maximum design load per fastener of 90 lbs. into concrete and 250 lbs. into structural steel. Some of our projects are in seismic design categories D, E, and F but the seismic design force does not always govern when checking against wind. In cases where seismic design force does not govern, are we allowed to use full capacity of these PAF fasteners regardless of the connection type for other loading applications?

ANSWER: When determining the number of PAF fasteners load combination calculations for gravity or wind design forces may use the full PAF capacity. However for seismic force load combination calculations the reduced capacity must be used. ANSWER: When determining the number of PAF fasteners load combination calculations for gravity or wind design forces may use the full PAF capacity. However for seismic force load combination calculations the reduced capacity must be used.

OCTOBER 2025

QUESTION: For multi-ply stud packs that get fastened together, we see different solutions from each of our structural engineering consultants. We see screws at 12"o.c. and 24"o.c. We also see connections that just require one screw and others that require two screws. QUESTION: For multi-ply stud packs that get fastened together, we see different solutions from each of our structural engineering consultants. We see screws at 12"o.c. and 24"o.c. We also see connections that just require one screw and others that require two screws.

What is the recommended on-center spacing of screws and what is number of screws for composite action (interaction) between the individual members of a stud pack?

ANSWER: The AISI S100-16 (2020) North American Specification for the Design of Cold-Formed Steel Structural Members with Supplement 2 Specification provides guidance for the design of built-up members, i.e. a stud pack. Section I1.2 provides design guidance regarding the member and connection design for a stud pack in compression. However, these provisions are limited to two sections. ANSWER: The AISI S100-16 (2020) North American Specification for the Design of Cold-Formed Steel Structural Members with Supplement 2 Specification provides guidance for the design of built-up members, i.e. a stud pack. Section I1.2 provides design guidance regarding the member and connection design for a stud pack in compression. However, these provisions are limited to two sections.

Based on extensive research, SDI-AISI-S100-2024, North American Specification for the Design of Cold-Formed Steel Structural Members Section I1.2 provides both prescriptive requirements and rational analysis for compression members composed of multiple cold-formed steel members. These design provisions are not limited to only two sections in contact in the stud pack.

The requirements of both editions of AISI S100 incorporate the on-center spacing of the intermediate fasteners and the required strength of the fastener connections. Note, these provisions apply only to the axis of buckling that requires shear force transfer between the individual sections.

SEPTEMBER 2025

QUESTION: Hello! We are designing an exterior wall CFS system (non-bearing) and hoping to use 10" deep studs with CRC bridging. We're finding documentation recommending against this. For example, AISI D110-16, Cold-Formed Steel Design Guide lists a disadvantage of CRC as not being effective for bridging studs with webs deeper than 8". However, I have found proprietary bridging that has capacities listed for bridging clips for 10" deep studs. What is your opinion on using CRC bridging with 10" deep studs? Another question our client has: is it possible to omit bridging clips in this case and weld the CRC directly to the 10" studs? QUESTION: Hello! We are designing an exterior wall CFS system (non-bearing) and hoping to use 10" deep studs with CRC bridging. We're finding documentation recommending against this. For example, AISI D110-16, Cold-Formed Steel Design Guide lists a disadvantage of CRC as not being effective for bridging studs with webs deeper than 8". However, I have found proprietary bridging that has capacities listed for bridging clips for 10" deep studs. What is your opinion on using CRC bridging with 10" deep studs? Another question our client has: is it possible to omit bridging clips in this case and weld the CRC directly to the 10" studs?

ANSWER: The D110 caution is based on a limited testing of standard CRC. Proprietary bridging solutions are available for deeper studs. The manufacturer has performed more extensive testing of their product and thus have determined that their bridging will brace the stud. ANSWER: The D110 caution is based on a limited testing of standard CRC. Proprietary bridging solutions are available for deeper studs. The manufacturer has performed more extensive testing of their product and thus have determined that their bridging will brace the stud.

Welding is permitted and it has been used to attach the bridging members directly to the stud web. However, for a 10” deep section, which will experience significant twisting under load, the omission of the clip is not recommended.

Considering the synergism of the assembly components, if sheathing is present in combination with the CRC a 10” stud should be adequately stabilized.

AUGUST 2025

QUESTION: AISI S220, North American Standard for Cold-Formed Steel Nonstructural Framing says that the axial load limit for non-structural members is: superimposed nominal axial load, exclusive of sheathing, of not more than 100 lb/ft, or not more than 200 lbs per stud. QUESTION: AISI S220, North American Standard for Cold-Formed Steel Nonstructural Framing says that the axial load limit for non-structural members is: superimposed nominal axial load, exclusive of sheathing, of not more than 100 lb/ft, or not more than 200 lbs per stud.

There are conditions where we have 2-hour and 3-hour fire rated stud walls where the wall has (2) or (3) layers of sheathing on each face. For tall walls, the weight of these layers can be way more than 100 lb/ft. Based on the standard language above, should this weight be Considered or Not Considered when evaluating the nominal axial load acting on the stud wall?

ANSWER: ANSWER:

Engineers generally interpret the Standard to mean that the weight of the sheathing should not be considered superimposed load. "Sheathing materials" may be thought of as including all non-ancillary or non-decorative layers. Since two and even three layers (of gypsum panel products) are commonly used, and fire tested as such, one would not consider any of the gypsum as part of the "superimposed" load.

This Standard requirement applies most often when interior partitions are supporting ceilings or floors from above. This discourages closely spaced nonstructural members used to support mezzanine floors.

JULY 2025

QUESTION: I have a question regarding AISI S240-20, Are there rules of thumb for span to depth ratios for cold-formed steel C-joists when looking at reasonable serviceability requirements? Is there is a range of span to depth ratios that helps ensure structural integrity and prevent excessive deflection or sagging under load? QUESTION: I have a question regarding AISI S240-20, Are there rules of thumb for span to depth ratios for cold-formed steel C-joists when looking at reasonable serviceability requirements? Is there is a range of span to depth ratios that helps ensure structural integrity and prevent excessive deflection or sagging under load?

Back in the day, the concrete, red iron and wood folks had these types of general limits for ‘practical’ serviceability.

ANSWER: ANSWER:

There are no recognized rules of thumb. Engineers typically have tools (e.g. software) and tables at their disposal to calculate joist requirements. However, in the absence of tools we are aware the following have been used for preliminary design estimates:

- half the span in feet = depth in inches” so a 20’ span would require 10” depth

- 20:1 span-to-depth ratio.

Even though shallower members could work, the “bounciness” and feel of the floor system could be problematic. Therefore, in addition to the code mandated L/360 for floors, some engineers use L/480 (live load only) for stiffer floors.

JUNE 2025

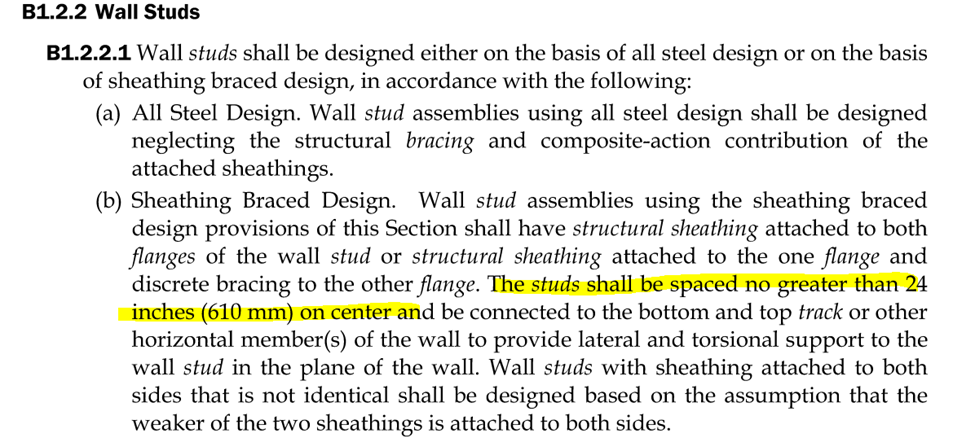

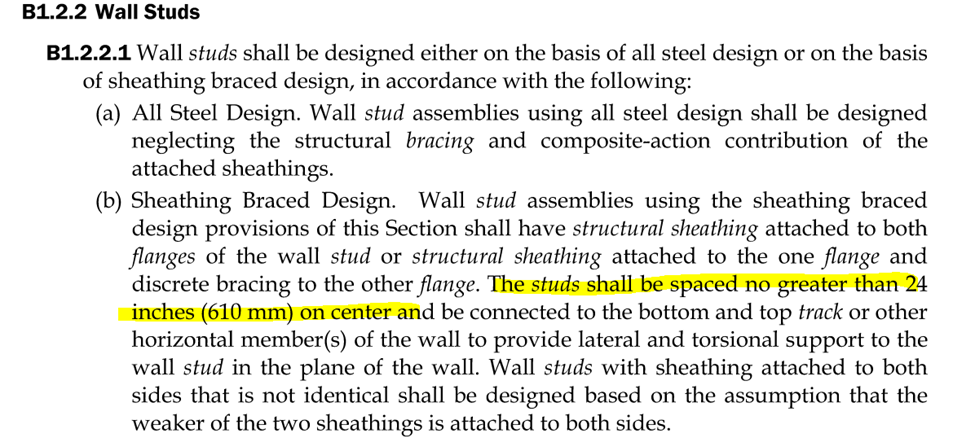

QUESTION: I have a question regarding AISI S240-20, North American Standard for Cold-Formed Steel Structural Framing, 2020 Edition. I noticed in the Wall Studs Section B1.2.2, this sentence was added. This was not stated in AISI S240-15, North American Standard for Cold-Formed Steel Structural Framing, 2015 Edition. Do you know what was the driving factor behind this? QUESTION: I have a question regarding AISI S240-20, North American Standard for Cold-Formed Steel Structural Framing, 2020 Edition. I noticed in the Wall Studs Section B1.2.2, this sentence was added. This was not stated in AISI S240-15, North American Standard for Cold-Formed Steel Structural Framing, 2015 Edition. Do you know what was the driving factor behind this?

ANSWER: ANSWER:

AISI S240-15 has a definition for “repetitive framing” which stipulated a maximum spacing of 24”. Thus, AISI S240-15 limited the use of the standard to assemblies having stud spacing not greater than 24” on center. AISI S240-20 deleted that definition and the 24” limit. Thus, enabling spacing greater than 24” on center were applicable.

The sentence you cited was added to Section B1.2.2.1 and other applicable design provisions that are based on testing/research studies where the maximum spacing was limited to 24”.

MAY 2025

QUESTION: ASTM C754-20 Section 5.3.2.1 states that jamb studs and corner studs are to be anchored to track flanges. For top track applications, where deflection of the structure above is to be accommodated, I do not see an exemption that these studs should not be mechanically fastened to the track. Is there any guidance available that specifies jamb studs and corner studs should not be mechanically fastened to top track in non-load bearing applications? QUESTION: ASTM C754-20 Section 5.3.2.1 states that jamb studs and corner studs are to be anchored to track flanges. For top track applications, where deflection of the structure above is to be accommodated, I do not see an exemption that these studs should not be mechanically fastened to the track. Is there any guidance available that specifies jamb studs and corner studs should not be mechanically fastened to top track in non-load bearing applications?

ANSWER: There is no code adopted exception for the top track jamb and corner stud connections. This requirement, for decades, has been in ASTM C754, Standard Specification for Installation of Steel Framing Members to Receive Screw-Attached Gypsum Panel Products. ANSWER: There is no code adopted exception for the top track jamb and corner stud connections. This requirement, for decades, has been in ASTM C754, Standard Specification for Installation of Steel Framing Members to Receive Screw-Attached Gypsum Panel Products.

ASTM C754 does require fastening of corner and jamb studs to top and bottom track, but this was written in a time when building floor-to-floor vertical deflection was less of an issue than it is today. These connections are still required, since ASTM C754 is directly referenced by Section C1 of AISI S220, North American Standard for Cold-Formed Steel Nonstructural Framing. However, the connection may be made using an alternate method to a screw from the track flange to the stud flange. Some alternate methods include a slotted track or a proprietary clip.

It should be noted that ASTM C754 stipulates that studs away from corners or jambs do not need to be attached to tracks. Section 5.3.1.3 states “Studs shall engage both the floor and ceiling runners”. The operative word is “engage”. Whereas Section 5.3.2.1 “Studs located adjacent to door and window frames, partition intersections, and corners shall be anchored to runner flanges by screws or crimping at each stud and runner flange”.

APRIL 2025

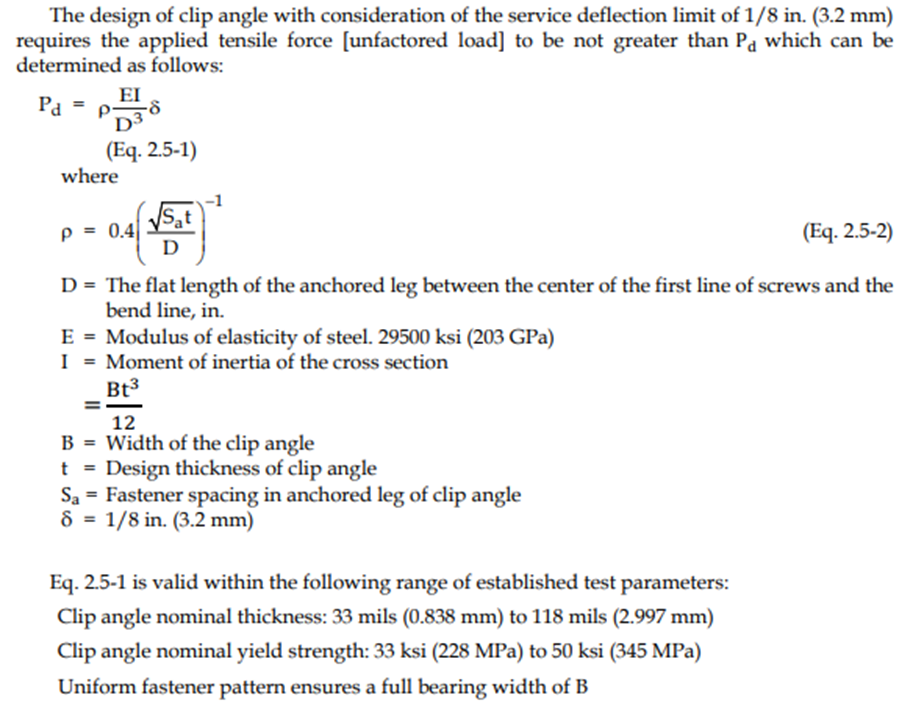

QUESTION: Why does AISI D114, Clip Angle Design Guide, not require consideration of prying action when evaluating the anchored leg of a clip angle? QUESTION: Why does AISI D114, Clip Angle Design Guide, not require consideration of prying action when evaluating the anchored leg of a clip angle?

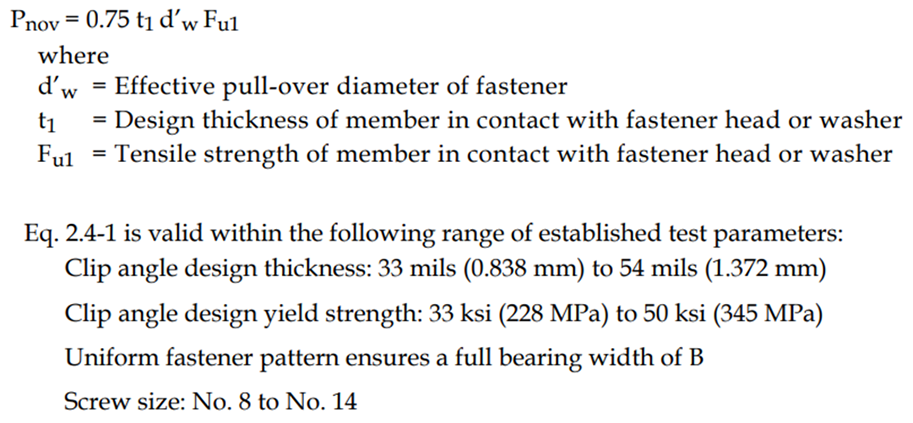

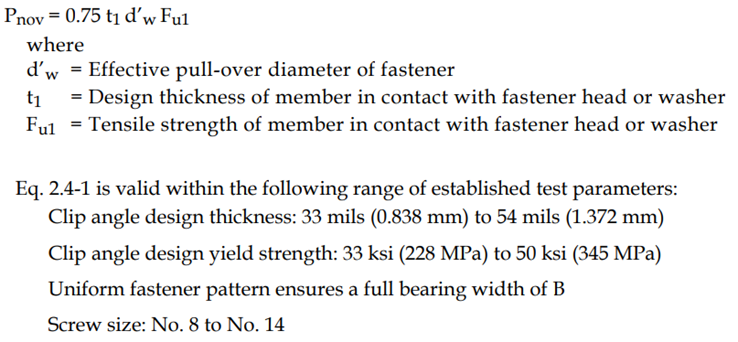

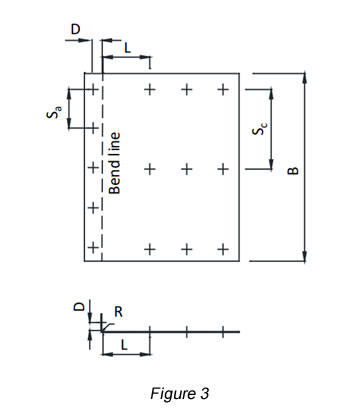

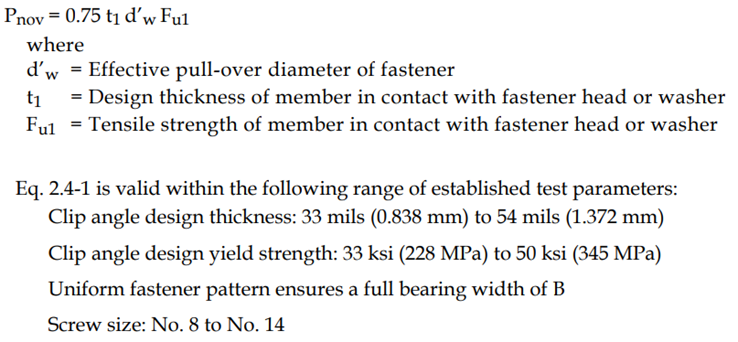

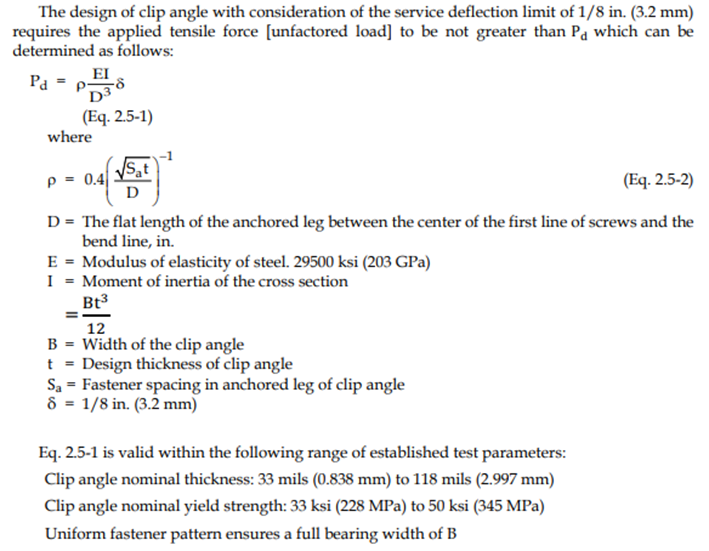

ANSWER: AISI D114 provides design guidance based on both a strength limit state and a deflection limit state for clip angles subject to tension. ANSWER: AISI D114 provides design guidance based on both a strength limit state and a deflection limit state for clip angles subject to tension.

Traditional limit states associated with the occurrence of prying action are:

- Bending failure of the connecting element (e.g. anchored clip leg)

- Tension failure of the fastener

Based on the UNT study on screw attached clips two additional strength limit states have been identified and are addressed in AISI D114:

- Pull-over of the anchored clip angle leg (Figure 1)

- Pull-out of the screw from the base material

D114 also imposes a deflection limit state.

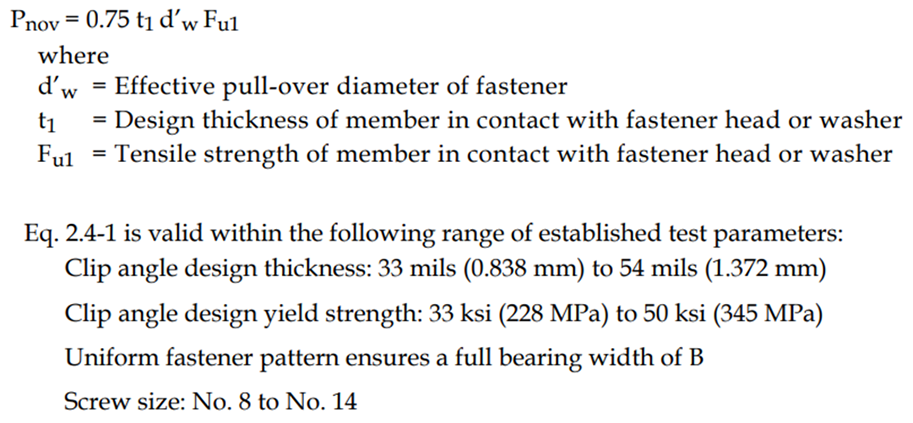

The pull-over strength limit state, Pnov is defined as,

The D114 deflection limit state is as follows:

Thus, because a deflection limit is imposed for thicker clip angles, within the scope of D114 the traditional prying action limit states are not a design consideration. Also, the UNT research determined that prying action is essentially eliminated at the peak load when the clip experiences shape changes.

MARCH 2025

QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing lists shear wall information with gypsum panels. IBC lists the same information. IBC also provides information for a gypsum sheathed horizontal diaphragm with wood framing, but not horizontal diaphragm with cold-formed steel joists. Is there a resource considering or discussing using the IBC gypsum over wood horizontal diaphragm capacities with cold-formed steel framing? Or just a direct resource discussing gypsum over cold-formed steel interior ceiling diaphragm capacities? QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing lists shear wall information with gypsum panels. IBC lists the same information. IBC also provides information for a gypsum sheathed horizontal diaphragm with wood framing, but not horizontal diaphragm with cold-formed steel joists. Is there a resource considering or discussing using the IBC gypsum over wood horizontal diaphragm capacities with cold-formed steel framing? Or just a direct resource discussing gypsum over cold-formed steel interior ceiling diaphragm capacities?

ANSWER: We are not aware of any additional documents beyond those you cited. Comparing the values from those documents can give a qualitative feel for the diaphragm capacity but would require judgment to apply to a design. ANSWER: We are not aware of any additional documents beyond those you cited. Comparing the values from those documents can give a qualitative feel for the diaphragm capacity but would require judgment to apply to a design.

FEBRUARY 2025

QUESTION: Is there a limit to how long a steel sheeted shear wall can be? Is it common to use the entire length of the building as a shear wall? QUESTION: Is there a limit to how long a steel sheeted shear wall can be? Is it common to use the entire length of the building as a shear wall?

ANSWER: There is no maximum shear wall length specified in S240, North American Standard for Cold-Formed Steel Structural Framing or S400, North American Standard for Seismic Design of Cold-Formed Steel Structural Systems so the length is often based on economic considerations. However, both AISI S240 and AISI S400 stipulate maximum shear wall aspect ratios, effectively setting minimum shear wall lengths for a given height. ANSWER: There is no maximum shear wall length specified in S240, North American Standard for Cold-Formed Steel Structural Framing or S400, North American Standard for Seismic Design of Cold-Formed Steel Structural Systems so the length is often based on economic considerations. However, both AISI S240 and AISI S400 stipulate maximum shear wall aspect ratios, effectively setting minimum shear wall lengths for a given height.

AISI S240 stipulates a maximum height-to-length ratio, h/w, as defined by Table B5.2.2.3-1. Whereas AISI S400 Table E2.3-1 provides the maximum height-to-length ratio, h/w, for seismic design.

When reviewing the respective tables note that footnote 3 provides additional guidance for computing the nominal strength for shear, Vn when h/w is greater than 2:1 but less than 4:1.

JANUARY 2025

QUESTION: I am designing a four-story CFS bearing wall building and am overwhelmed by the different member options and not sure what industry standards are for many variables (ie stud width, gauge, Fy). We know our walls will be 6" thick but I am unsure of any variable beyond that and find several combinations of size/gauge/Fy may work for my studs and headers. My question is: QUESTION: I am designing a four-story CFS bearing wall building and am overwhelmed by the different member options and not sure what industry standards are for many variables (ie stud width, gauge, Fy). We know our walls will be 6" thick but I am unsure of any variable beyond that and find several combinations of size/gauge/Fy may work for my studs and headers. My question is:

- Should we just design everything to the lowest possible tonnage of steel and just assume all stud shapes/gauges/Fy are all easily available?

- Or is it better to use only a few different sizes of stud/header that are easy to tell apart to avoid miss instillation?

- Are there various stud type or header type that are very hard to get?

ANSWER: The following is input from one CFSEI member. These are possible guidelines to consider when designing a multi-story structure. ANSWER: The following is input from one CFSEI member. These are possible guidelines to consider when designing a multi-story structure.

- Be consistent on a single floor. For example, most of the studs on the 4th floor will be the same, but they will be different from those on the 3rd floor or 2nd floor. Therefore, optimize per floor.

- It is best to design the most commonly used members to the lowest possible size, then consider using that member at a tighter spacing in higher load areas.

- For jambs, it may be possible to use built-up members that are the same as the adjacent studs, but often designers will use a larger flange stud at jambs since that is much easier for field identification and differentiation. For example, if the typical wall studs are 600S162-54, the jamb studs may be something like 600S300-54, which is wide enough that a framer will easily see the difference.

- Many contractors cannot easily differentiate between thickness if the thicknesses are close, and the rest of the stud dimensions are the same.

- Not all stud types/sizes are commonly available in all thicknesses. Check with your contractor or supplier on preferences and availability.

- Contractors prefer a wider flange to a heavier thickness.

- The most common default flange for wall studs is 1-5/8”. (e.g. 600S162-43).

- Headers are usually specified as unpunched, to avoid shear and web crippling issues.

- Headers do not need to be the same depths as wall studs (okay to use an 8” header in a 6” wall).

- Always specify mil thickness rather than gauge thickness. There are several different thicknesses that are considered 20 gauge, so using mil thickness reduces the chance of error.

- For 33 and 43 mil thickness, yield strength is typically 33 KSI, and for 54 and heavier thicknesses, yield strength is typically 50 KSI. CFSEI is currently developing a Tech Note that will include differing opinions/guidelines from several engineers. Look for the Tech Note later in the year.

DECEMBER 2024

QUESTION:

Why is my limiting height value smaller for Fy = 50 ksi than for Fy = 33 ksi?

ANSWER:

For thin cold-formed steel cross sections local buckling impacts both strength and stiffness. The following figure illustrates local buckling of the compression flange. Local buckling can be thought of as a softening of the cross section. The cross section is no longer working to its full potential.

Using the Effective Width Method of Appendix 1 of AISI S100, the following numerical values illustrate the impact of local buckling for a 6” deep 33 mil profile:

|

Fy

(ksi)

|

Ma

(in-kips)

|

Ixd

(in^4)

|

|

33

|

14.31

|

2.3326

|

|

50

|

19.79

|

2.2927

|

|

70

|

23.13

|

2.2554

|

NOVEMBER 2024

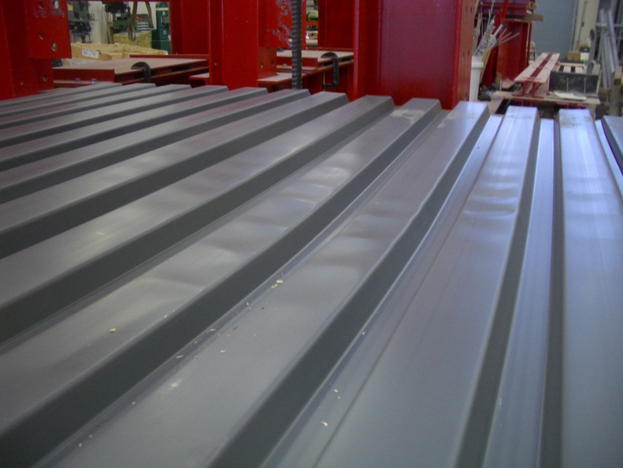

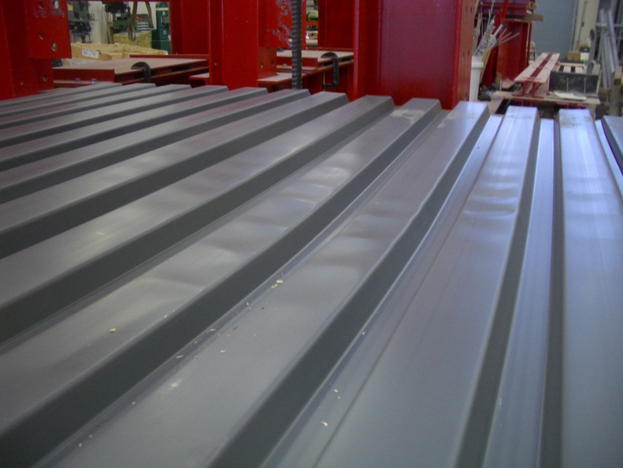

QUESTION:

I have a question regarding steel flat sheets per AISI S400. Section E2.4.1.1 (l) states that if the steel sheets are lapped at the edges with no blocking, the capacities have a reduction factor of 0.7. Does this reduction only apply to the tabulated values in Table E2.3-1? If we use the effective strip method to calculate capacities, can we lap the sheets without this reduction?

|

|

E2.4 System Requirements

E2.4.1 Type I Shear Walls

E2.4.1.1 Limitations for Tabulated Systems

|

|

(I)

|

In lieu of panel blocking, unblocked assemblies with panel edges are permitted to be overlapped and attached to each other with screw spacing as required for panel edges. Where such a connection is used, the nominal strength [resistance] provided in Table E2.3-1 is to be multiplied by 0.70.

|

| |

ANSWER:

The effective strip method assumed continuous sheathing. If the sheets are lapped, the same reduction factor can reasonably be applied.

OCTOBER 2024 OCTOBER 2024

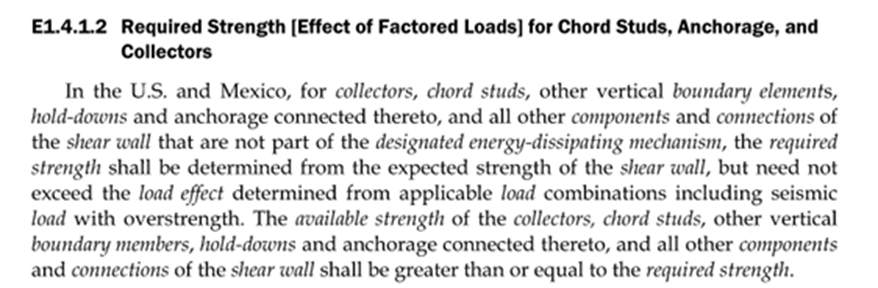

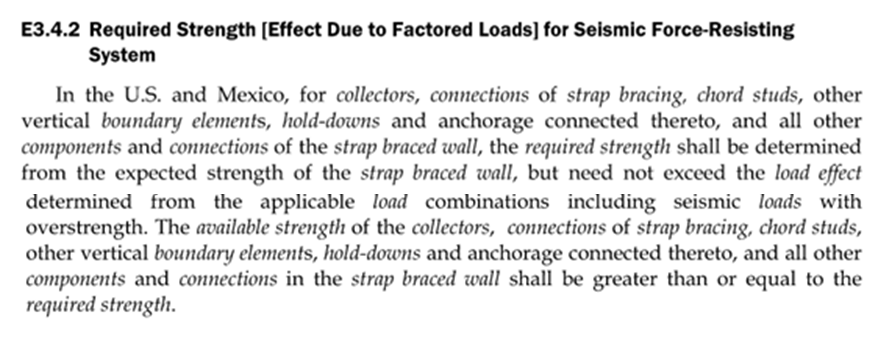

QUESTION: Just for my clarity as the verbiage change in S400-20 is not as direct as S400-15. The below verbiage just seems to be removed from each assembly section. Would the following still apply for shear walls and strap braced walls in S400-20?

Cold Formed walls w/ Wood Sheathing (from S400-15):

Strap Braced Walls (from S400-15):

Also do you know of any published design examples following the steps of S400-20?

ANSWER:

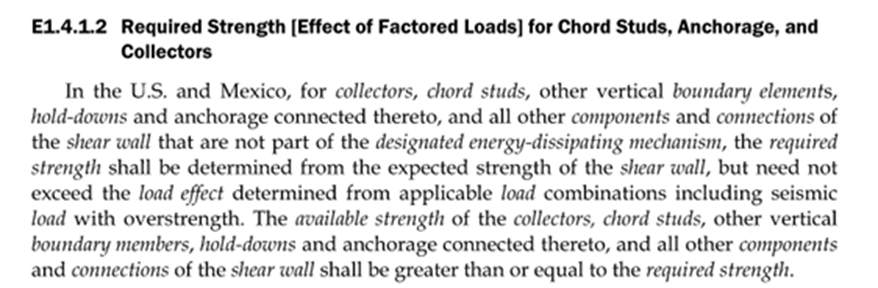

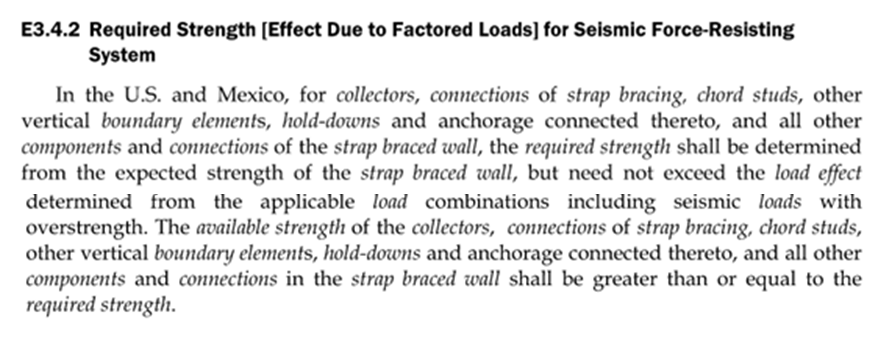

To eliminate the repetitive listing of the various elements that require consideration of expected strength or overstrength, AISI S400-20 defined “capacity protected components”. Section B3 provides the design requirements for these components. Each SFRS has its own list of capacity protected components. For example, for wood structural panel shear walls, Section E1.4.1.2 lists the capacity protected components. The Commentary for Section E1.4.1.2 also discusses “Capacity Protected Components”. To eliminate the repetitive listing of the various elements that require consideration of expected strength or overstrength, AISI S400-20 defined “capacity protected components”. Section B3 provides the design requirements for these components. Each SFRS has its own list of capacity protected components. For example, for wood structural panel shear walls, Section E1.4.1.2 lists the capacity protected components. The Commentary for Section E1.4.1.2 also discusses “Capacity Protected Components”.

Although, not based on AISI S400-20, AISI D113-19, Cold-Formed Steel Shear Wall Design Guide, illustrates the design procedure for the consideration of expected strength and overstrength. Determination of the overstrength factor, ΩE, is updated in S400-20, but application of the factor is as illustrated in D113-19. Information regarding AISI D113-19 can be found at https://buildsteel.org/technical/codes-and-standards/aisi-releases-cold-formed-steel-shear-wall-design-guide-2019-edition/

SEPTEMBER 2024 SEPTEMBER 2024

QUESTION: AISI S240-20 Section B5.2.1.2 (b) states:"(b) For a Type II shear wall, the nominal strength [resistance] for shear, Vn, is based upon a screw spacing of not less than 4 inches (100mm) on center." Does this imply that 4" is the minimum screw spacing at the sheathing panel edges and the respective capacities are limited to 4" spacing, i.e. 2" and 3" spacings shown in tables B5.2.2.3-1 and B5.2.2.3-2 cannot be used.

ANSWER:

The tabulated values are based on test results. Because there has been limited testing for the Type II shear wall the intent of the referenced provision is to limit the nominal capacity, Vn, to the 4/12 or 6/12 values. The field spacing is intended to remain 12” oc. The tabulated values are based on test results. Because there has been limited testing for the Type II shear wall the intent of the referenced provision is to limit the nominal capacity, Vn, to the 4/12 or 6/12 values. The field spacing is intended to remain 12” oc.

AUGUST 2024 AUGUST 2024

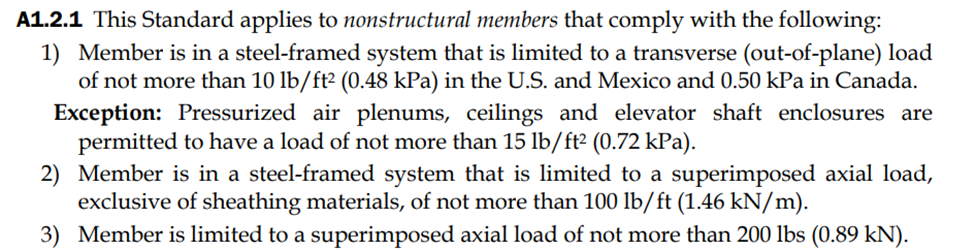

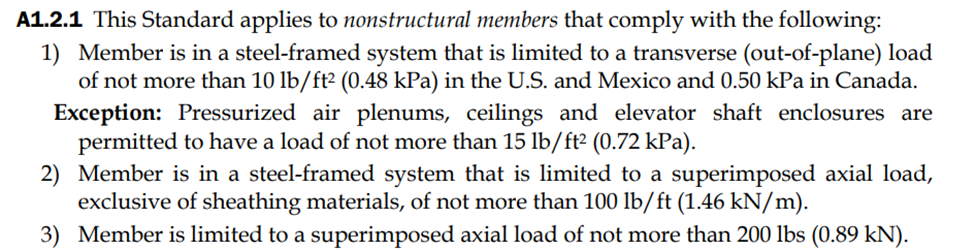

QUESTION: AISI S220, North American Standard for Cold-Formed Steel Nonstructural Framing, Section A1.2.1 has the following limitations:

I am struggling with limit No. 2. For example, doesn’t a 100 lb/ft of superimposed axial load, exclusive of sheathing material, negate limitation No. 3?

ANSWER: ANSWER:

The key to Section A1.2.1 limitations is that all the limitations must be met for a member to be considered nonstructural. Also, limitations 1 and 2 apply to systems, i.e., members in a wall system, whereas limitation 3 applies to each member only.

So, it would be okay to support a piece of equipment that is 300 lbs if the load is distributed over the length of the wall and no individual member was assigned to support more than 200 lbs.

Limit 2 applies most often when interior partitions are supporting ceilings or floors from above. This discourages closely spaced nonstructural members used to support mezzanine floors.

JULY 2024 JULY 2024

QUESTION: Hello - I was curious if you were aware of a typical detail you could point me to as a starting point for typical penetrations through plywood sheathed light frame stud shear walls. I work as a structural engineer, and we are trying to specify the appropriate detailing for new duct penetrations through a new shear wall. The duct penetrations are roughly 30"x30” but vary in size across the building. Any assistance would be greatly appreciated.

ANSWER: ANSWER:

There is no document that specifically addresses force transfer around openings for cold-formed steel framing. However, the APA Technical Note T555A “Design of Force Transfer Around Openings (FTAO)” summarizes the design concept and technical issues regarding force transfer around openings. The document is a download from https://www.apawood.org/ftao.

JUNE 2024 JUNE 2024

QUESTION: Currently, I am involved in design cold-formed steel framing. Honestly, I am facing the difficulty to locate information to gain an understanding the cold-formed steel framing design. While in school I didn’t study any material related to cold-formed steel design. In the school syllabus, they focused more on concrete structures and hot-rolled steel structures. I am trying to find material for cold-formed steel design, but there is not much to find. Therefore, I emailed you to get more information about cold-formed steel framing.

My question is:

Could you be please guide me with some recommendations and references (book, class note, online sources, training etc.) on how I can improve my skills on cold-formed steel framing design to build a strong background on the subject?

ANSWER: ANSWER:

There are several educational opportunities available.

- CFSEI has just developed a new six-hour lecture series that introduces the AISI S100 design specification. This on-demand webinar provides a basic understanding of the behavior and design principles for cold-formed steel members and connections. This lecture series will be available at https://cfseiondemand.com/aisi-standard-courses/

- CFSEI also provides Tech Notes as well as other webinars that are available at www.cfsei.org.

MAY 2024 MAY 2024

QUESTION: I am working on a large senior housing project which is required to have 2-hour protection of all structural components: bearing walls, columns and floor-ceiling assemblies. I would like to confirm the requirements for meeting this 2-hour rating (particularly for the walls), preferably in the form of UL listings. The structure is assumed to be bearing walls at corridors and exterior walls. Typical floor-ceiling assembly of upper floors and roof are to be 18" deep trusses. The other specific aspect I would like to confirm, is if there is any height limitation to meeting the 2-hour rating requirement as the ground floor has a 16'-0" floor-to-floor height.

ANSWER: Thank you for your email. The “requirements for meeting this 2-hour rating” are to pass an ASTM E119 fire test. All UL listed assemblies have passed the E119 requirements, which include a burn test and for wall assemblies a hose-stream test. ANSWER: Thank you for your email. The “requirements for meeting this 2-hour rating” are to pass an ASTM E119 fire test. All UL listed assemblies have passed the E119 requirements, which include a burn test and for wall assemblies a hose-stream test.

You may find the following two documents helpful:

There are multiple 2-hour assemblies for both load-bearing and non-load bearing cold-formed steel framed walls, and structural floor-ceiling and roof-ceiling assemblies.

For these assembles, there are no height limitations other than the structural capacities of the members themselves. So as long as structural analysis shows that the members can span your project’s 16’ height and they meet the UL design requirements, then there is no additional height limitation requirement from the fire rating.

APRIL 2024 APRIL 2024

QUESTION: Does AISI D114, Clip Angle Design Guide, require consideration of prying action when evaluating the anchored leg of a clip angle?

ANSWER: AISI D114 provides design guidance based on both a strength limit state and a deflection limit state for clip angles subject to tension. ANSWER: AISI D114 provides design guidance based on both a strength limit state and a deflection limit state for clip angles subject to tension.

Traditional limit states associated with prying action are:

- Bending failure of the connecting element (e.g. anchored clip leg).

- Tension failure of the fastener.

However, based on the University of North Texas study on thin screw attached clips two additional strength limit states were identified and are addressed in AISI D114:

- Pull-over of the anchored clip angle leg (Figure 1).

- Pull-out of the screw from the base material.

The pull-over strength limit state, Pnov is defined as,

The pull-over strength design equation was calibrated to test results. Thus, any prying effects are included in the design equation. Therefore, prying effects need not be considered. But for the pull-out strength and screw tension strength evaluations, the prying effects should be considered.

The D114 deflection limit state is as follows:

Based on the UNT testing, for thicker clip angles, the 1/8” deflection limit was achieved prior to a failure of the clip angle. Thus, when applying the AISI D114 design methods because a deflection limit is imposed for clip angles thicker than 54 mils the traditional prying action limit states are not a design consideration.

However, if the 1/8” deflection limit is not imposed as a design limit state, then prying action should be considered when evaluating the following limit states:

- Bending failure of the connecting element (e.g. anchored clip leg)

- Tension failure of the fastener

- Pull-over of the anchored clip angle leg.

- Pull-out of the fastener from the base material.

MARCH 2024 MARCH 2024

QUESTION: Why does AISI D114-21, Cold-Formed Steel Clip Angle Design Guide, not consider the bending limit state?

ANSWER: AISI D114 is providing design guidance. The design equations are not code adopted. ANSWER: AISI D114 is providing design guidance. The design equations are not code adopted.

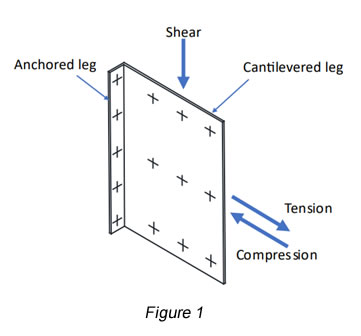

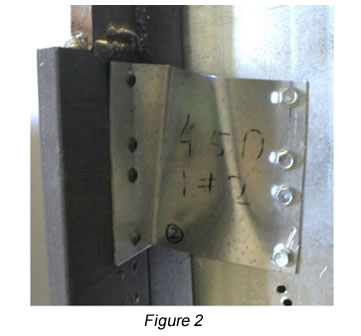

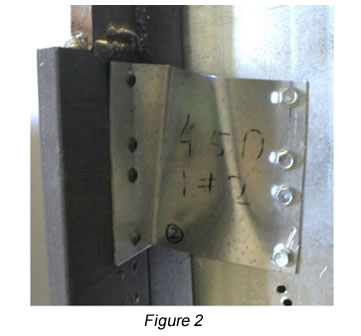

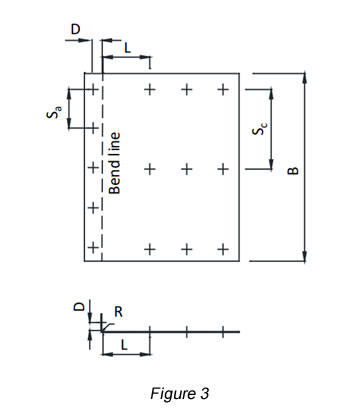

When subjected to a shear load (Figure 1), a clip angle is structurally analogous to a short cantilever beam. Based on research at the University of North Texas, the typical clip angle failure occurs in a panel of length L by depth B (Figures 2 and 3). Thus, the aspect ratio for the failure panel is defined as L/B.

A beam is generally regarded as a “deep beam” when its shear span-to-depth ratio, L/B, is < 2.0. Because a clip angle may typically have an L/B ratio equal to or less than 2.0 they exhibit behavior consistent with a deep beam. Also, as defined by AISI D114, the equations are limited to clips having L/B < 1.4.

The main difference between a shallow beam (typical floor joist or curtain wall stud) and a deep beam is that in the case of a shallow beam shear deformations are negligible and could be ignored while shear deformations must be considered in the analysis and design of a deep beam.

Because of the geometry of deep beams, their behavior is different from shallow beams. Deep beams are shear dominant and shallow beams are flexure dominant. Thus, the clip angle predominantly fails in shear rather than flexure because it has a small L/B ratio.

FEBRUARY 2024

QUESTION: My question pertains to strap splices in strap braced shear walls. Can we splice the strap itself? We have a large shear wall, and the client wants to splice the strap. Considering that these straps are loaded in tension, I would think a simple 24" long reinforcing strap of same width and gauge centered on splice and screwed on each side of the splice with enough screws to develop the full tension capacity of the strap or at least to develop the applied tension load per strap. Are there negative sides or issues with splicing straps? QUESTION: My question pertains to strap splices in strap braced shear walls. Can we splice the strap itself? We have a large shear wall, and the client wants to splice the strap. Considering that these straps are loaded in tension, I would think a simple 24" long reinforcing strap of same width and gauge centered on splice and screwed on each side of the splice with enough screws to develop the full tension capacity of the strap or at least to develop the applied tension load per strap. Are there negative sides or issues with splicing straps?

ANSWER: ANSWER:  Splicing of a strap is not prohibited in either AISI S240, North American Standard for Cold-Formed Steel Structural Framing or AISI S400, North American Specification for the Design of Cold-Formed Steel Structural Members. However, both yielding and rupture at the splice connection will need to be considered. Also, if the design includes seismic forces, the splice design should be based on the expected strength of the straps, or the seismic force including overstrength, Ω0. Splicing of a strap is not prohibited in either AISI S240, North American Standard for Cold-Formed Steel Structural Framing or AISI S400, North American Specification for the Design of Cold-Formed Steel Structural Members. However, both yielding and rupture at the splice connection will need to be considered. Also, if the design includes seismic forces, the splice design should be based on the expected strength of the straps, or the seismic force including overstrength, Ω0.

JANUARY 2024

QUESTION: My purchasing department has been unable to obtain ASTM A1003. But A653 is readily available. May I use A653 for cold-formed steel members? QUESTION: My purchasing department has been unable to obtain ASTM A1003. But A653 is readily available. May I use A653 for cold-formed steel members?

ANSWER: As discussed by CFSEI Tech Note G801, cold-formed steel framing was traditionally manufactured from galvanized, Galvalume® or Galfan® sheet steel complying with the requirements of ASTM A653, A792 or A875, respectively. One of the purposes of the ASTM A1003 standard was to provide a common standard for these various materials to simplify the process for the specifier and supplier. ANSWER: As discussed by CFSEI Tech Note G801, cold-formed steel framing was traditionally manufactured from galvanized, Galvalume® or Galfan® sheet steel complying with the requirements of ASTM A653, A792 or A875, respectively. One of the purposes of the ASTM A1003 standard was to provide a common standard for these various materials to simplify the process for the specifier and supplier.

ASTM A1003 was developed to be inclusive of the former ASTM A653, A792 and A875 standards, provide additional options for suppliers, and be consistent with the material requirements of the AISI S240, North American Standard for Cold-Formed Steel Structural Framing.

The AISI S240 Section A3.1 User Note states:

“ASTM A1003 was developed to be inclusive of ASTM A653/A653M, A792/A492M, A875/A875M and A1063/A1063M standards. For more information see CFSEI Tech Note G801. Therefore, products furnished to these material standards meet the requirements of A1003/A1003M.”

DECEMBER 2023

QUESTION: I have designed the hold-downs and anchorage of my shear wall for overstrength or expected strength. Do I now need to design the foundation for these elevated forces? QUESTION: I have designed the hold-downs and anchorage of my shear wall for overstrength or expected strength. Do I now need to design the foundation for these elevated forces?

ANSWER: For designs using AISI S400, the hold-down and anchorage device are required to be designed with consideration given to overstrength. ANSWER: For designs using AISI S400, the hold-down and anchorage device are required to be designed with consideration given to overstrength.

However, In the United States and Mexico, for foundations, the required strength shall be determined from the seismic load effect and need not include the overstrength factor (Ωo) nor consider the expected strength of the seismic force-resisting system unless otherwise specified in the applicable building code.

The following User Note has been adopted for the next edition of AISI S400:

“In the United States and Mexico, the design of the foundation itself need not consider overstrength or expected strength. However, hold-downs and anchorage into the foundation are capacity protected components. Design of these components, including limit states associated with failure of the foundation material (e.g. concrete breakout, side face blowout, anchor pullout and pryout) must meet the required strength provisions of Section B3.”

A similar user note has not been adopted for the next edition of AISI S240 because S240 is limited to design for an R value of 3.

NOVEMBER 2023

QUESTION: I have a quick question regarding metal stud shear walls sheathed with OSB or plywood. When sheathing panels are installed with their long sides vertical, do panel joints need to be staggered? QUESTION: I have a quick question regarding metal stud shear walls sheathed with OSB or plywood. When sheathing panels are installed with their long sides vertical, do panel joints need to be staggered?

ANSWER: The only requirement in AISI S240 applicable to this question: ANSWER: The only requirement in AISI S240 applicable to this question:

- Section B5.2.2.3.1 (g) – All sheathing edges are attached to structural members or panel blocking, unless otherwise specified.

- Section B5.2.2.3.3 (b) – Wood structural panels are applied either parallel to or perpendicular to studs.

In AISI S400:

- Section E1.4..1.1 (k) – All sheathing edges are attached to structural members or panels.

S240 and S400 do not have a requirement.

However, good practice would recommend staggering joints no matter what orientation of the panels.

OCTOBER 2023

QUESTION: I am evaluating an existing metal building built in the 70s. I am trying to confirm what grade of steel was likely used for the cold-formed steel Z-purlins. Since they're 7" and 12 ga thick, I assumed they are at least 50 ksi yield strength. However, there may have been a different grade of steel available back then. I am just trying to see if that is a possibility. QUESTION: I am evaluating an existing metal building built in the 70s. I am trying to confirm what grade of steel was likely used for the cold-formed steel Z-purlins. Since they're 7" and 12 ga thick, I assumed they are at least 50 ksi yield strength. However, there may have been a different grade of steel available back then. I am just trying to see if that is a possibility.

ANSWER: The Metal Building Manufacturers Association has a technical publication that is intended to provide some ideas and insights into how a metal building can be retrofitted or reinforced. See page 12 for a discussion of the material properties for purlins and frames. ANSWER: The Metal Building Manufacturers Association has a technical publication that is intended to provide some ideas and insights into how a metal building can be retrofitted or reinforced. See page 12 for a discussion of the material properties for purlins and frames.

SEPTEMBER 2023

QUESTION: The AISI shear provisions only seem to cover screw capacities for steel-to-steel connections. I have a condition on a project where I need to check the shear strength of screws through gypsum board and into a cold-formed steel stud. Specifically, I have a track ledger that is placed directly against a wall with (2) layers of gypsum board. The screws attach through the track ledger, through the (2) layers of 5/8" gypsum board, and into the stud flange. The track is in direct contact with the gypsum board, not the stud. The track ledger is also receiving joists. Are there published values for this type of condition? I'd like to know even if it’s just (1) layer of gypsum board. Is this even a code-accepted connection? Any insight you have will be greatly appreciated. QUESTION: The AISI shear provisions only seem to cover screw capacities for steel-to-steel connections. I have a condition on a project where I need to check the shear strength of screws through gypsum board and into a cold-formed steel stud. Specifically, I have a track ledger that is placed directly against a wall with (2) layers of gypsum board. The screws attach through the track ledger, through the (2) layers of 5/8" gypsum board, and into the stud flange. The track is in direct contact with the gypsum board, not the stud. The track ledger is also receiving joists. Are there published values for this type of condition? I'd like to know even if it’s just (1) layer of gypsum board. Is this even a code-accepted connection? Any insight you have will be greatly appreciated.

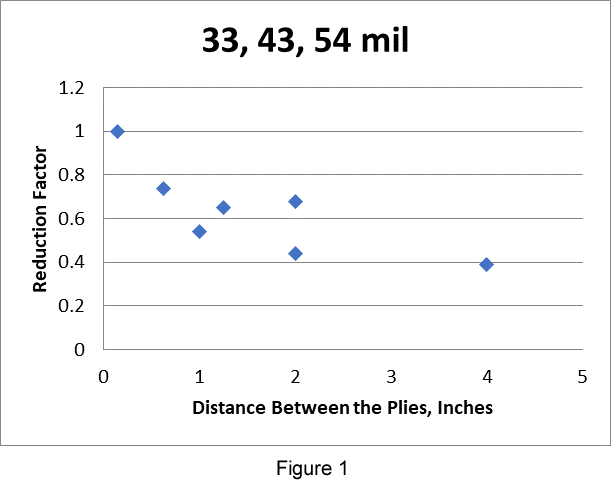

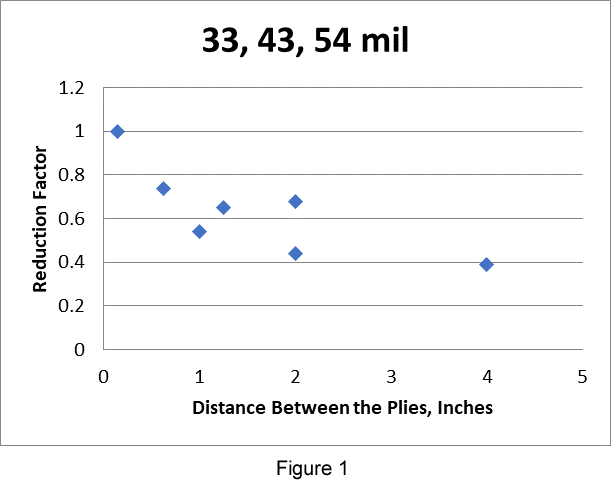

ANSWER: Currently the AISI Specification does not have criteria for the connection with material between the plies. Based on limited data regarding the connection behavior as illustrated by Figure 1, CFSEI Tech Note F602, Screw Connections with Other Materials or Gaps Between the Plies, was developed. The Tech Note provides design guidance regarding the evaluation of the strength of a connection. ANSWER: Currently the AISI Specification does not have criteria for the connection with material between the plies. Based on limited data regarding the connection behavior as illustrated by Figure 1, CFSEI Tech Note F602, Screw Connections with Other Materials or Gaps Between the Plies, was developed. The Tech Note provides design guidance regarding the evaluation of the strength of a connection.

AUGUST 2023

QUESTION: Is there a group fastener modification factor for multiple screws or are the attached cold-formed steel members considered rigid and all of the fasteners are considered equally loaded? QUESTION: Is there a group fastener modification factor for multiple screws or are the attached cold-formed steel members considered rigid and all of the fasteners are considered equally loaded?

ANSWER: The equations in AISI S100 Section J4 are based on tests results. The assumption made when the test results were evaluated was that all of the screws shared the load equally. ANSWER: The equations in AISI S100 Section J4 are based on tests results. The assumption made when the test results were evaluated was that all of the screws shared the load equally.

JULY 2023

QUESTION: I am designing a parapet wall for a new project. I need help with the connection of a 362S162-54. QUESTION: I am designing a parapet wall for a new project. I need help with the connection of a 362S162-54.

ANSWER: AISI D110-16, Cold-Formed Steel Framing Design Guide, offers some discussion regarding parapet walls. The discussion begins on PDF page 113. AISI D110 may be purchased at American Iron and Steel Institute Store. ANSWER: AISI D110-16, Cold-Formed Steel Framing Design Guide, offers some discussion regarding parapet walls. The discussion begins on PDF page 113. AISI D110 may be purchased at American Iron and Steel Institute Store.

Click here to purchase

|

QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing requires a 0.35 reduction be applied for gypsum sheathed shear walls without blocking. It then requires all horizontal applied sheathing be panel blocked. We have engineers interpret this differently. Some will say all gypsum shear walls must be panel blocked and the 0.35 is for panels not having solid wall blocking. Others interpret this as allowing no panel blocking if you hit the capacity by 0.35. Can you help clarify how these two requirements relate and/or where this 0.35 comes from so we can put this to bed?

QUESTION: AISI S240, North American Standard for Cold-Formed Steel Structural Framing requires a 0.35 reduction be applied for gypsum sheathed shear walls without blocking. It then requires all horizontal applied sheathing be panel blocked. We have engineers interpret this differently. Some will say all gypsum shear walls must be panel blocked and the 0.35 is for panels not having solid wall blocking. Others interpret this as allowing no panel blocking if you hit the capacity by 0.35. Can you help clarify how these two requirements relate and/or where this 0.35 comes from so we can put this to bed? ANSWER: The following is proposed language to be added to the SFIA AISI S240, North American Standard for Cold-Formed Steel Structural Framing, 2026 Edition

ANSWER: The following is proposed language to be added to the SFIA AISI S240, North American Standard for Cold-Formed Steel Structural Framing, 2026 Edition

Splicing of a strap is not prohibited in either AISI S240,

Splicing of a strap is not prohibited in either AISI S240,