2020 CFSEI CREATIVE DETAIL AWARD WINNER

SECOND PLACE

COLD-FORMED STEEL EXPERT, LLC – THE PRADO – SANDY SPRINGS, GEORGIA

The Prado Sandy Springs The Prado Sandy Springs

5560 Roswell Road, NE

Sandy Springs, Georgia 30328

Owner: North American Development Group.

Architect of Record: Victor Yue, Dorsky + Yue International Architecture, LLC

Engineer of Record for Structural Work: Aaron D. Lobas, P.E., S.E.

Cold-Formed Steel Specialty Contractor: Premier Construction Services, Inc.

Award Entry Submitted by: Zsolt V. Nemedi, P.E., M.S.C.E., Cold-Formed Steel Expert, LLC.

Project Background

The project focused on the design of the new facade of the existing concrete masonry unit (CMU) building incorporating the unique architectural feature of the wingwall and the eyebrow. The project focused on the design of the new facade of the existing concrete masonry unit (CMU) building incorporating the unique architectural feature of the wingwall and the eyebrow.

Design Challenges and Solutions

The design challenges included:

- Cold-formed steel (CFS) wingwall cantilevers up above the CMU framing.

- CFS cantilevers out beyond the corner of the building.

- Wingwall does NOT extend down to the foundation.

- There is no in-plane support.

- Wingwall must be tied back for both lateral and vertical loads to CMU wall over two feet away.

- Limited width for work with a total thickness of 12 inches, leaving only 8 inches for CFS framing.

- Corner zone and parapet winds.

Design Concepts

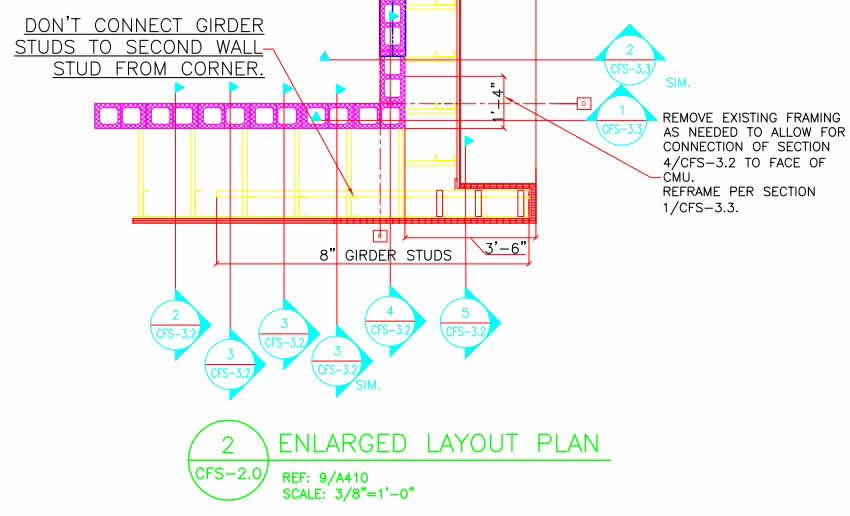

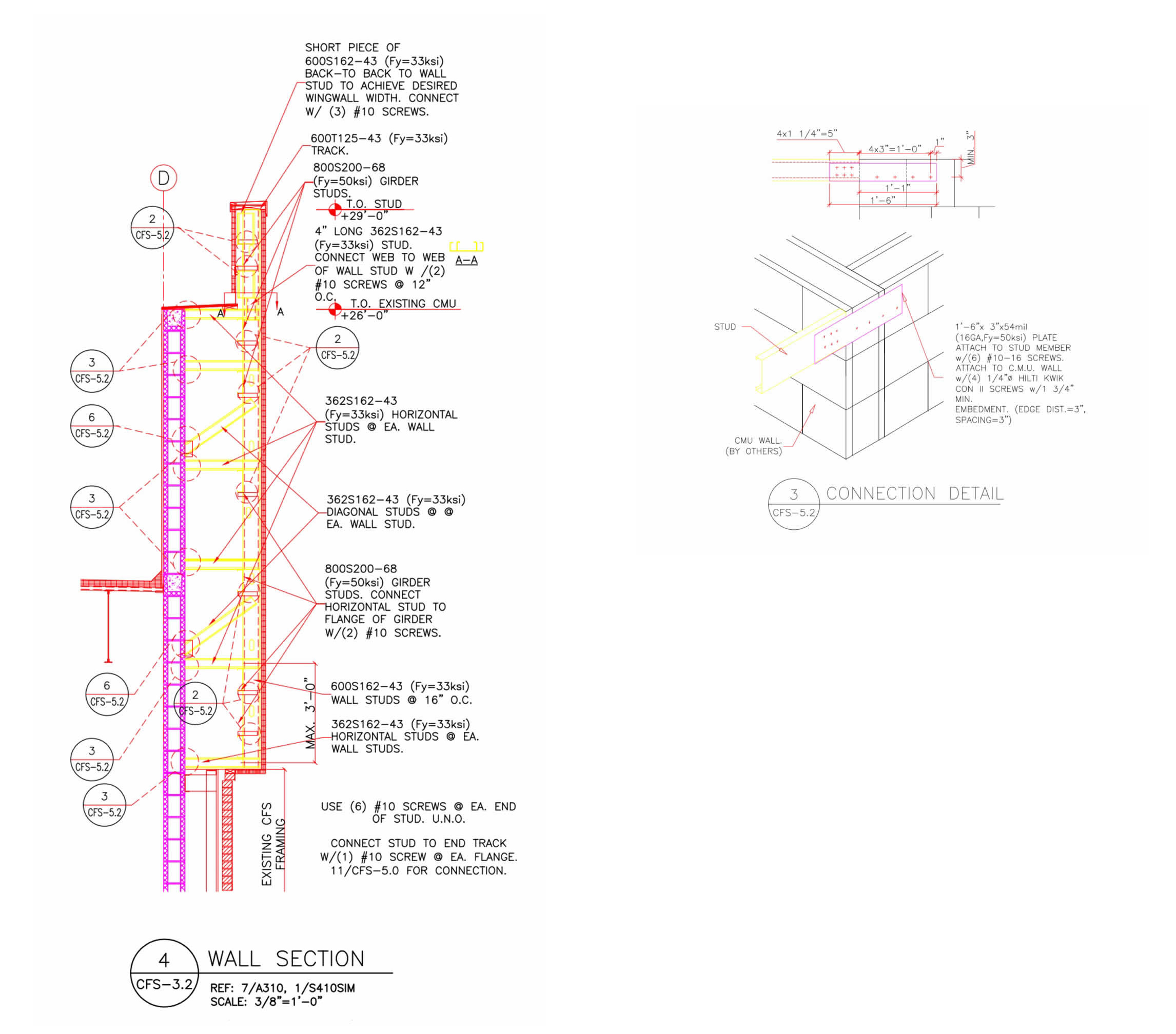

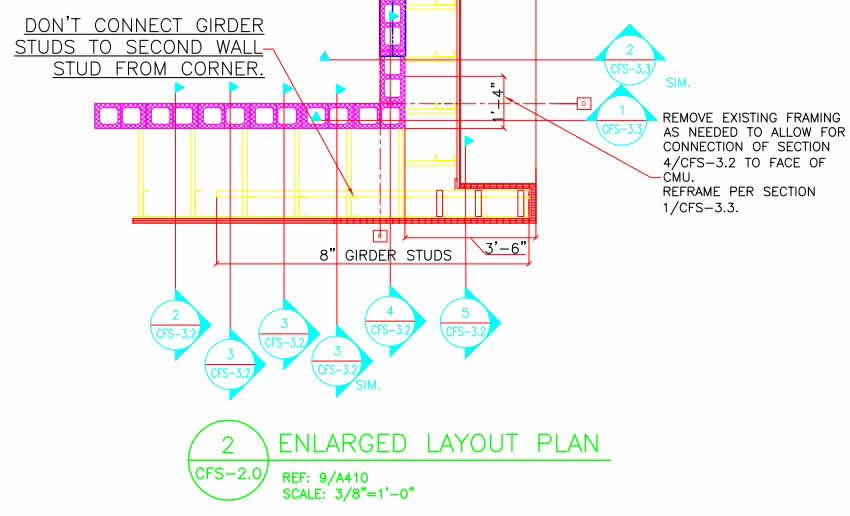

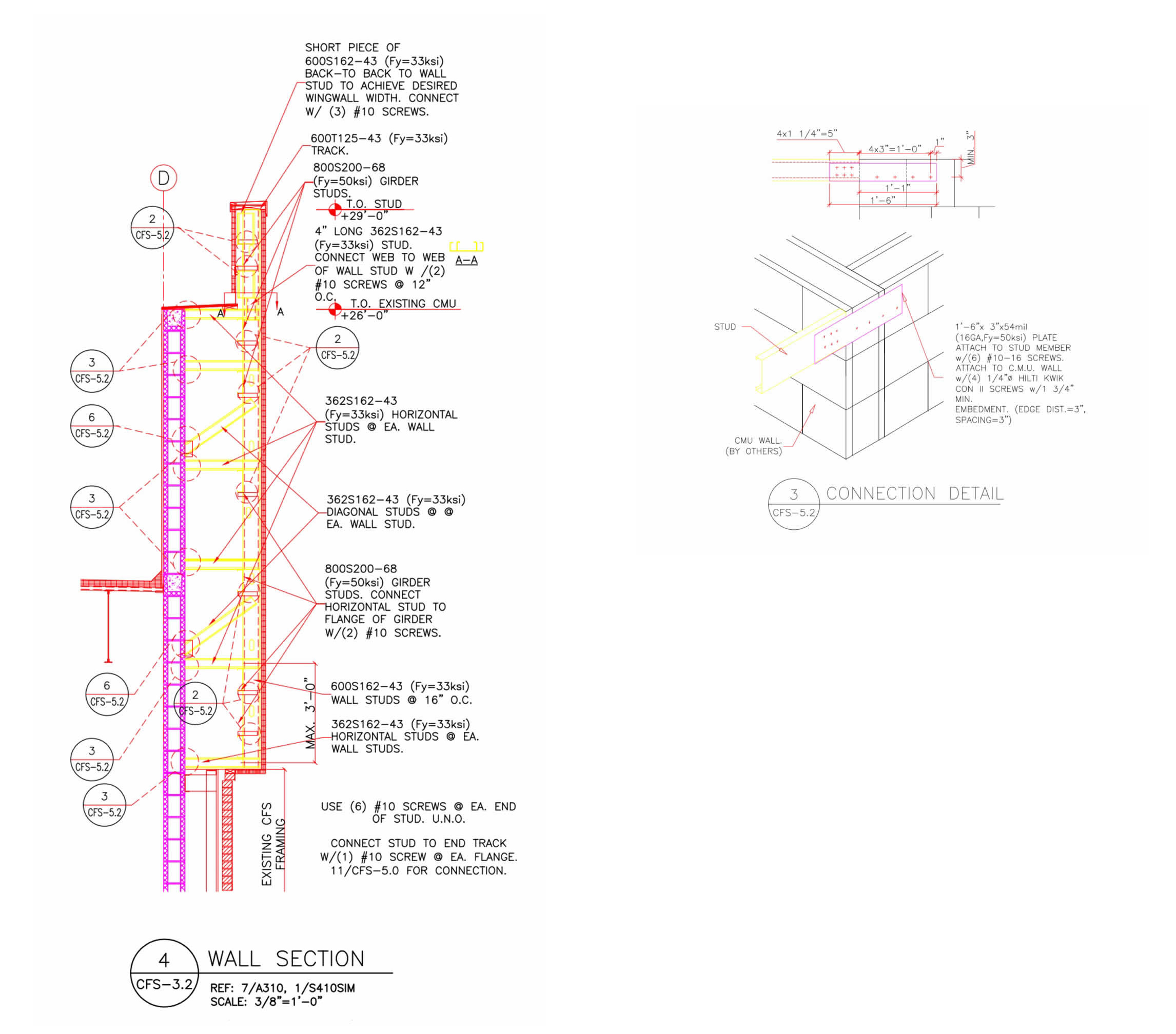

The team started with the 3.5-foot horizontal cantilever. The 6-inch vertical studs were supported laterally and vertically by 8x2 horizontal studs, making full use of the narrow 8-inch space available. The 8-inch studs were analyzed as multiple span cantilevered beams in both the weak and strong axis. The two-span condition was a better solution than the three-span condition. When multiple-span beams are cantilevered, the last two reactions are large and opposite, so by relieving the second support, the team was able to reduce the first and largest reaction. The team started with the 3.5-foot horizontal cantilever. The 6-inch vertical studs were supported laterally and vertically by 8x2 horizontal studs, making full use of the narrow 8-inch space available. The 8-inch studs were analyzed as multiple span cantilevered beams in both the weak and strong axis. The two-span condition was a better solution than the three-span condition. When multiple-span beams are cantilevered, the last two reactions are large and opposite, so by relieving the second support, the team was able to reduce the first and largest reaction.

From the corner, the first, third and fourth frames support the horizontal cantilever. Since this wall does not extend down to the slab and there are no in-plane supports, these frames are acting as trusses by transferring the loads back to the CMU. The vertical member extends up, cantilevering beyond the top of the CMU. As noted, the first frame at the corner had the largest reaction (1,600 lbs). To satisfy the spacing and edge distance requirements, this challenge was handled with tension plates with a 13-inch lap over the CMU.

The horizontal eyebrow framing presented a smaller challenge. It is also cantilevered out but is not supported (vertically) by the wing wall.

|