2023 CFSEI DESIGN EXCELLENCE AWARD WINNERS

SECOND PLACE – COMMERCIAL

R.A. SMITH, INC. – STARBUCKS

STATEN ISLAND, NEW YORK

Starbucks Starbucks

1717 Richmond Road

Staten Island, NY 10021

Completion Date: Fall 2022

Owner: Starbucks

Architect of Record: Gambino & LaPorta Architecture, PC

Cold-Formed Steel Specialty Engineer: Alyssa Pease, R.A. Smith, Inc.

Cold-Formed Steel Specialty Contractor: Don Allen, Super Stud Building Products, Inc.

Award Entry Submitted by: Alyssa Pease, R.A. Smith, Inc.

Project Background

Starbucks, an American company and the largest coffeehouse chain in the world, operates over 30,000 locations in more than 70 countries. Starbucks is a roaster and retailer of whole bean coffee, ground coffee, tea, and spices, and a place for conversation and a sense of community; a third place between home and work. With over 300,000 employees, Starbucks' mission is “to inspire and nurture the human spirit – one person, one cup, and one neighborhood at a time.

The Lighthouse Hill neighborhood, a chain of hills that radiate from the northeast corner of Staten Island, New York, was the site for a new Starbucks coffeehouse. The single store, a free-standing building, located at 1717 Richmond Road, offers a drive-through window for high-traffic street access with convenient ingress and egress, and the configuration is adaptable to a variety of alternative uses. The design reflects the Starbucks mission statement by nurturing the human spirit and the community of Staten Island.

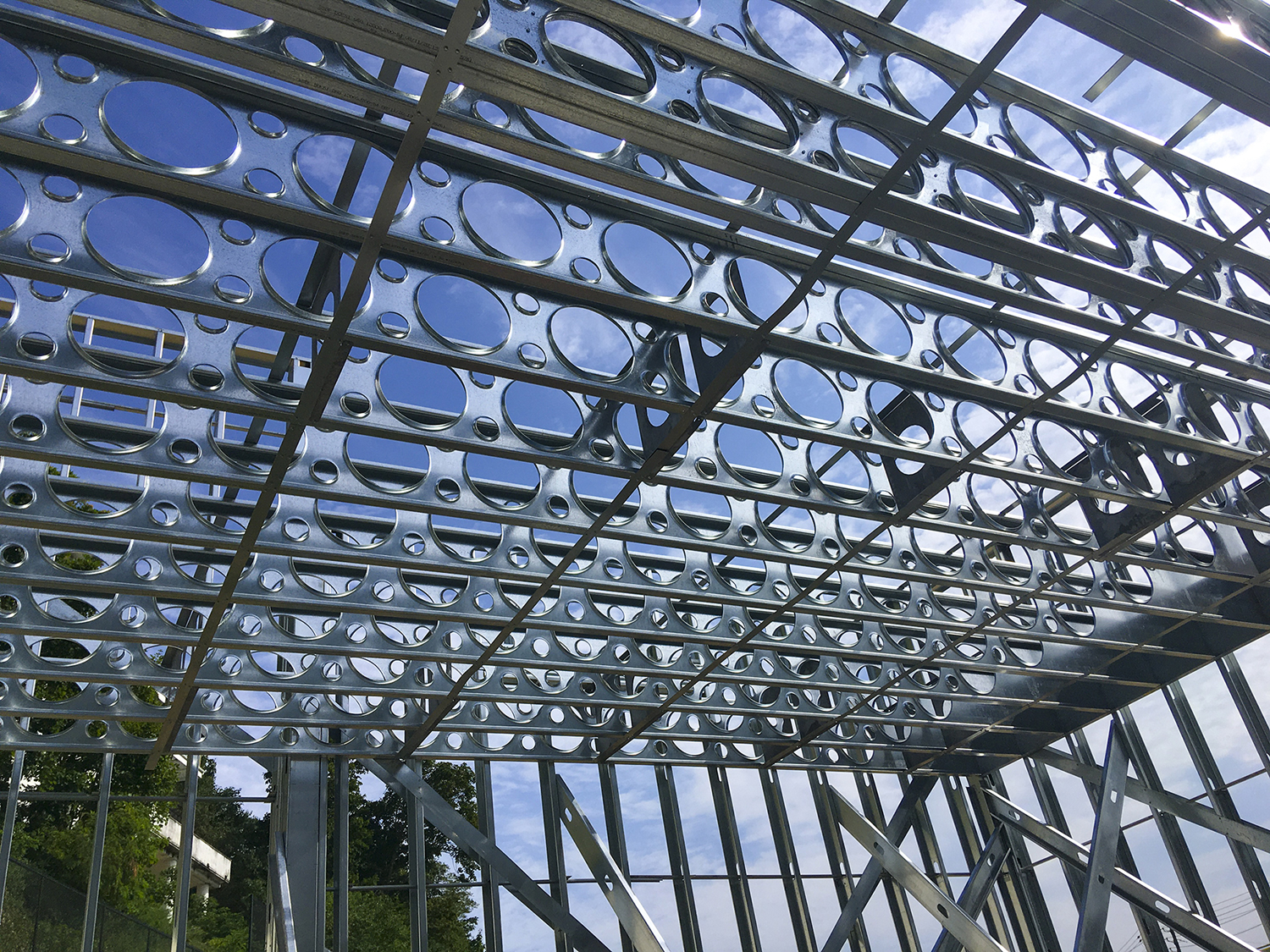

The Richmond Road Starbucks is an 1,875-square-foot, single-story, load bearing cold-formed steel structure on a cast-in-place concrete foundation. The exterior steel stud walls are primarily sheathed with a hard-coat stucco exterior insulation finish system (EIFS) over DensGlass®, with some accents of 6-inch solid cedar shiplap planks. The roof consists of an EPDM system over corrugated metal deck supported by SuperMaxx joists. An additional amenity includes cold-formed framed canopies over the drive-through storefront and entrance areas. The Richmond Road Starbucks is an 1,875-square-foot, single-story, load bearing cold-formed steel structure on a cast-in-place concrete foundation. The exterior steel stud walls are primarily sheathed with a hard-coat stucco exterior insulation finish system (EIFS) over DensGlass®, with some accents of 6-inch solid cedar shiplap planks. The roof consists of an EPDM system over corrugated metal deck supported by SuperMaxx joists. An additional amenity includes cold-formed framed canopies over the drive-through storefront and entrance areas.

Design Challenges and Solutions

To the untrained eye, the Richmond Road Starbucks may appear as a simple structure— a single-story, 1,875-square-foot rectangular-shaped building with man doors, storefront openings with protruding canopies and an area on the roof utilizing a screen wall. However, making these features work together successfully in a load bearing cold-formed steel structure required a significant and creative engineering effort.

SuperStud Building Products was responsible for providing all cold-formed steel framing members and brought R.A. Smith, Inc. into the project to utilize their cold-formed steel design expertise. Some of the primary design challenges for the project were 3 ½-foot-tall perimeter parapet walls, 8 ½-foot-tall mechanical screen walls, 28-foot simple span roof framing, storefront openings with cantilevering canopies and shear wall design. SuperStud Building Products was responsible for providing all cold-formed steel framing members and brought R.A. Smith, Inc. into the project to utilize their cold-formed steel design expertise. Some of the primary design challenges for the project were 3 ½-foot-tall perimeter parapet walls, 8 ½-foot-tall mechanical screen walls, 28-foot simple span roof framing, storefront openings with cantilevering canopies and shear wall design.

The east side of the building brought many of these design challenges together. The framing supports not only the roof, but also a bump-out in the structure with a canopy that cantilevers off the bump-out and main structure. The canopy structure is a large header off the end that is supported at three locations across the bump-out. On the far north side, the header supporting the canopy cantilevers off the final support outrigger. By doing this, we were able to achieve the architectural feature of a canopy that appears to effortlessly continue across the building regardless of the support structure below.

The mechanical screen wall presented its own challenge due to height, wind load and support structure. There was no structural steel provided to support this wall; therefore, framing was designed to span between joists to distribute the load from the screen wall above. These connections proved difficult due to the fasteners having to pass through clips, metal deck, and then align to go into the cold-formed blocking below. To ensure there was no deck crushing, wood blocking was recommended in areas where this connection occurred. The mechanical screen wall presented its own challenge due to height, wind load and support structure. There was no structural steel provided to support this wall; therefore, framing was designed to span between joists to distribute the load from the screen wall above. These connections proved difficult due to the fasteners having to pass through clips, metal deck, and then align to go into the cold-formed blocking below. To ensure there was no deck crushing, wood blocking was recommended in areas where this connection occurred.

The shear walls on this job were interesting to design. With all of the canopies and openings, the design team had to find wall locations large enough to support the lateral forces. In the end, three of the structure's corners presented enough space for the team to utilize X-braced straps.

These are just a few examples of the many challenges that were considered in coordination of this project.

Click here for shop drawings

- Details of note at canopy; 14,21,22,31/CF3.2

- Sections of note at canopy; 3/CF2.1, 5,7/CF2.2

- Details of note at screen wall; 4,5/CF3.1

- Sections of note at screen wall; 6/CF2.2

- Details of note at shear walls; 28,29/CF3.2

- Sections of note at shear walls; 15/CF2.4

|