2018 CFSEI DESIGN EXCELLENCE AWARD WINNERFIRST PLACE/MUNICIPALFRAMEWORKS ENGINEERING – TRINIDAD BAPTIST CHURCH, CAPITOL HEIGHTS, MD

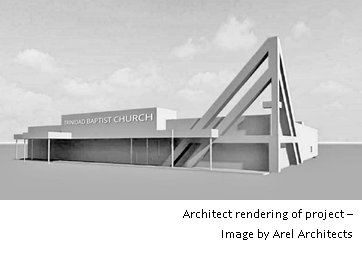

Completed: June 2017 Owner: Trinidad Baptist Church Architect of Record: Arel Architects Engineer of Record for Structural Work: SEG INC. Cold-Formed Steel Specialty Engineer: Robert Warr, P.E., Frameworks Engineering Cold-Formed Steel Specialty Contractor: Barry Unger, Panel Systems, Inc. Award Entry Submitted by: Robert Warr, P.E., Frameworks Engineering Project Background

Design Challenges Several unique design challenges were associated with the triangle feature:

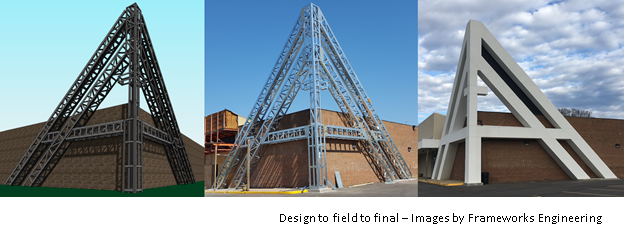

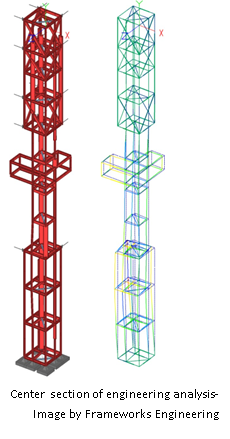

Design Solutions The Trinidad Baptist Church project showcases the design flexibility and adaptability of cold-formed steel framing and application of modern-day engineering practices. It highlights prefabrication, 3-D framing analysis, and Building Information Modeling (BIM) drawing and detailing. Intricate coordination was critical among the design team, since many of the elements Frameworks Engineering incorporated a concept to allow the architectural dimensions of the feature, which was critical to the center cross feature. The frame had to stay within the outer limits and be flush so that any finish would not show building of the framing. This was an initial problem due to a portion of the center mast section that was more slender than the rest. Since the center mast did not have any direct connection to the existing building but was only connected at its base, the sides of the feature needed to support the center mast section and the frame had to be reconfigured in order to place the trussed internal members to resist internal forces. Also critical to the design was deflection within the members to accommodate the stained glass. As part of the collaboration, Frameworks Engineering changed the glass size within the feature to allow for an expansion joint channel capable of supporting the movement due to the deflection results in the final design. This prevented the design from being too rigid for the structure so it could flex, and also allowed the glass to remain in place without damage.

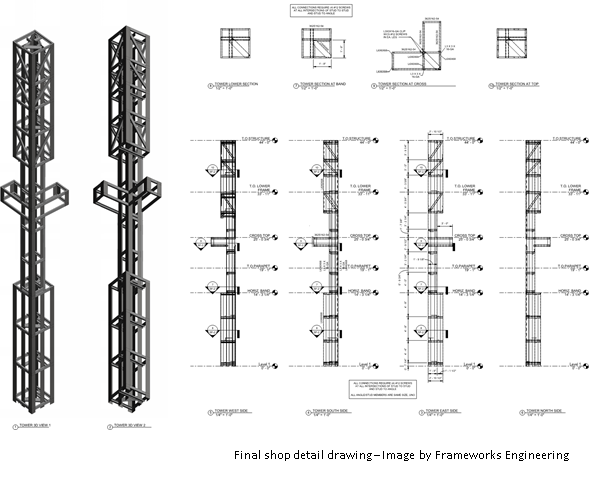

The design started with extreme loading of the feature, wind corner zone wall loading and parapet loading. Since it was prefabricated, Revit® BIM software was used to leverage the model to create detailed shop drawings of the separate sections. This allowed Frameworks Engineering to export the analytical model to a structural analysis program and then update the Revit® model based on the results. This process quickly exposed a problem with using red-iron steel for the mast area. Since the top of the mast was very heavy, the weight caused excessive deflection and member failure. In order to eliminate the red-iron steel, Frameworks Engineering developed a flat plate thin sheet cold-formed steel connection that would reduce the weight at the top of the feature while providing the strength required to support the center mast section. The analysis also allowed Frameworks Engineering to identify all of the various load combination reactions, which was essential to determining the interconnections of the feature sections and the connection to the building and its foundation. The feature was connected to a reinforced masonry wall based on anchorage limits of the CMU. Also, the locations of the anchorage had to be accessible in the field by reaching within the cold-formed steel frame. In the end, the connections were located and spaced to achieve the physical prefabrication access points and material limitations.

The deflection was a very important part of the success of the design. The analysis approach allowed the team to better predict the deflection limits, which led to the negotiation of the stained glass insert. Once the design was finalized, Frameworks Engineering continued the detailing efforts using Revit® to produce assembled design drawings. The sections were then broken down to fabricated shop drawing sets, which included information on handling limitations in the shop, on the truck, and in the field. Cold-formed steel framing, a cohesive project team and design flexibility resulted in a unique and aesthetically interesting corner feature for the newly renovated Trinidad Baptist Church. |

Trinidad Baptist Church

Trinidad Baptist Church

All of these challenges made it quickly evident that advanced framing analysis would be required in order to design the feature in the most efficient manner and then quickly run all scenarios of loading.

All of these challenges made it quickly evident that advanced framing analysis would be required in order to design the feature in the most efficient manner and then quickly run all scenarios of loading.