2022 CFSEI DESIGN EXCELLENCE AWARD WINNERS

THIRD PLACE – MUNICIPAL/SERVICES

CLARKDIETRICH ENGINEERING SERVICES - PORTMIAMI TERMINAL V

MIAMI, FLORIDA

PortMiami Terminal V PortMiami Terminal V

718 N Cruise Blvd

Miami, Florida 33132

Completed: February 13, 2022

Construction Cost: $180 million

Owner: Virgin Voyages

Architect of Record: Juan Marcos Fernandez, Bermello Ajamil & Partners, Inc.

Engineer of Record for Structural Work: Alex Lopez, P.E., DDA Engineers, P.A.

Cold-Formed Steel Specialty Engineer: Garrett Hippert, ClarkDietrich Engineering Services

Cold-Formed Steel Specialty Contractor: Hector Montas, Acousti Engineering Company of Florida

Award Entry Submitted by: Garrett Hippert, ClarkDietrich Engineering Services

Project Background

The PortMiami Terminal V in Miami, Florida is a $180 million, 122,500 square foot structure which serves as a home port for cruises originating out of Miami. The building was commissioned by Virgin Voyages to service, supply and transfer guests on its new fleet of cruise ships. In addition to its unique look and modern amenities, the structure also utilizes sustainable features including a multitude of skylights to make use of natural lighting.

Design Challenges and Solutions

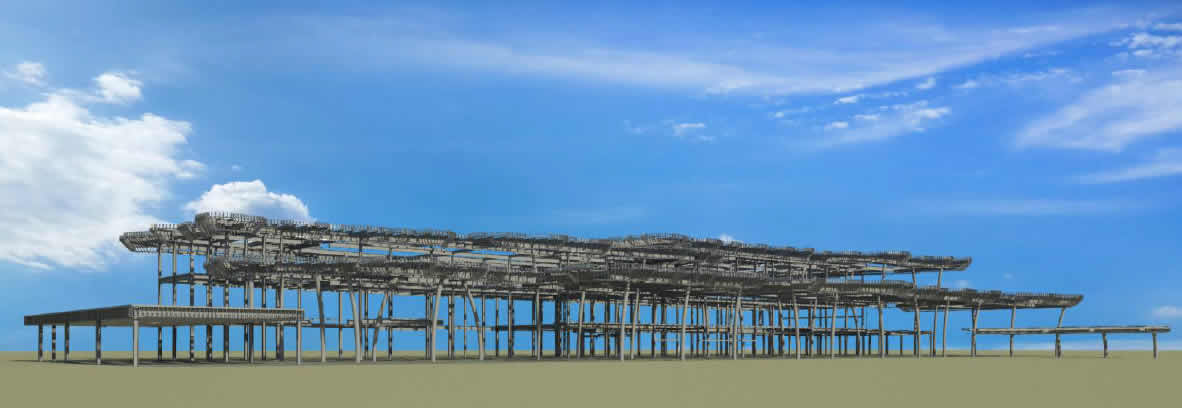

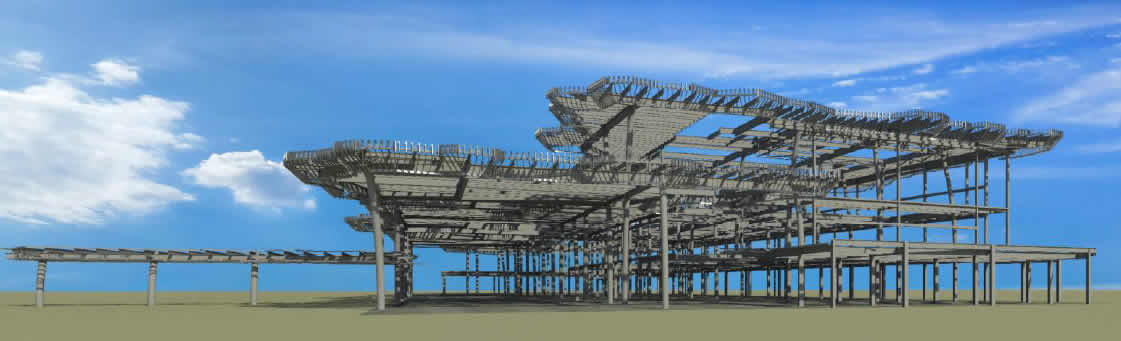

Acousti Engineering Company of Florida was contracted to complete the cold formed steel framing on the interior and exterior of the terminal. The team faced with many framing challenges due to the complex shapes, slopes, and constant direction changes which can be seen on the canopy’s perimeter and skylights of the building. ClarkDietrich Engineering Services was chosen to create a framing scheme unique to this structure that would solve many of the challenges in an efficient and cost-effective way for Acousti. This was accomplished through shop drawing submittals for both the interior and exterior of the building as well as a Building Information Modeling (BIM) model of the exterior canopies and skylights.

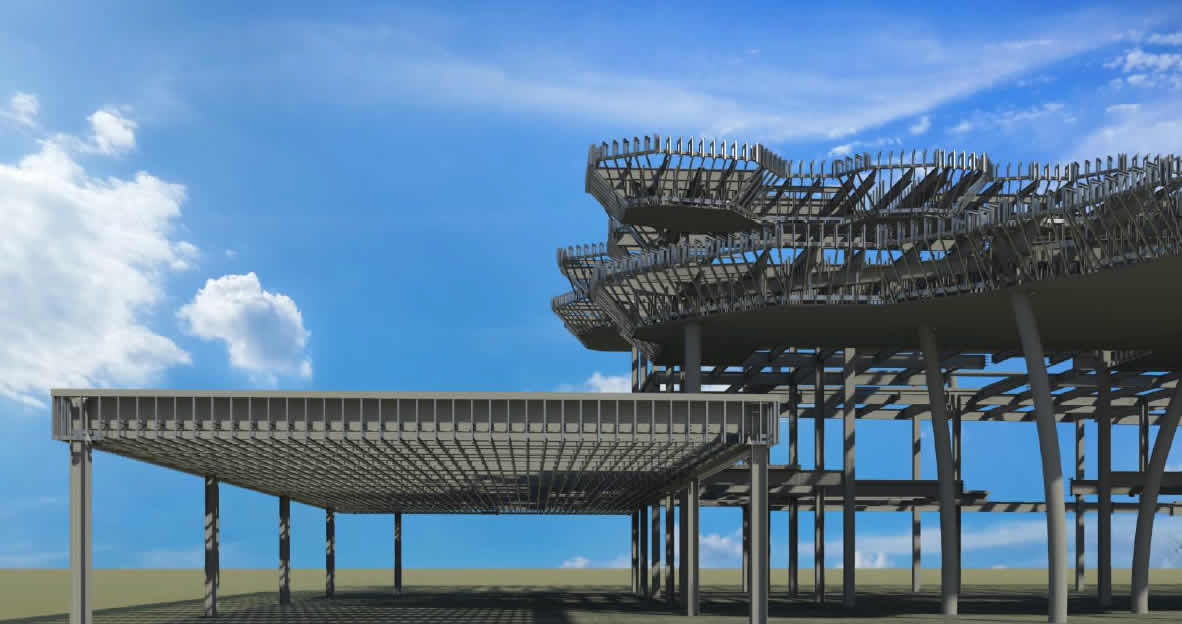

The engineering team at ClarkDietrich started work on the job during its preliminary stages to determine framing schemes that would meet the design requirements. They also aided the Acousti team with producing their own perimeter framing mockup. Once all the contract documents were finalized, the ClarkDietrich team produced shop drawings which included reference plans, section cuts, and framing details for all interior and exterior walls, soffits and canopy framing. The architect's design included canopies with constantly changing angled perimeters intended to resemble the canopy of a forest. Due to its ever-changing nature, ClarkDietrich Engineers decided to create a set of parameters for each aspect of the perimeter’s design including the perimeter frame itself, the collector frames occurring at both concave and convex corners, and the strongbacks. Parameters were also provided for the skylight areas which had similarly challenging shapes. The engineering team also coordinated with the GRFC manufacturer's shop drawings to verify framing parameters would comply with the panel attachments, ensuring no discrepancies during installation. All of these different aspects provided Acousti with clearly defined ways to handle all possible situations they would likely encounter while in the field.

The engineering team was also required to interpret wind tunnel test loads and summarize the data to create wind load ranges for cold-formed framing design. Because of its unusual footprint and location in an area affected by hurricanes, certain parts of the building experienced very high forces that required stronger designs. Converting the wind load data into ranges allowed for an optimized design process, so only a few different variations of frames and supports were needed for the full range of loading. It also allowed for frames to be value engineered, ensuring certain areas were not overbuilt just because other areas had higher wind load considerations.

To help reduce the construction time for this project, the BIM team coordinated and modeled every stud frame around the perimeter and skylights to give a complete virtual reference that could be used by Acousti. A major benefit of creating the BIM model is it made clear any interferences or problem areas early in the construction process. This made it possible to address any issues before they were found in the field, saving time during the installation process.

A combination of hard work and coordination between the engineering and BIM teams helped Terminal V become a reality. The design and modeling methods used proved highly effective in ensuring that the cold-formed framing aspects of the job were constructed without issue. Opened on February 13, 2022, Virgin Voyages Terminal V is an impressive and unique structure that excites guests, while also providing a host of essential services to the cruise line.

|