2022 CFSEI DESIGN EXCELLENCE AWARD WINNERS

FIRST PLACE – MUNICIPAL/SPORTS

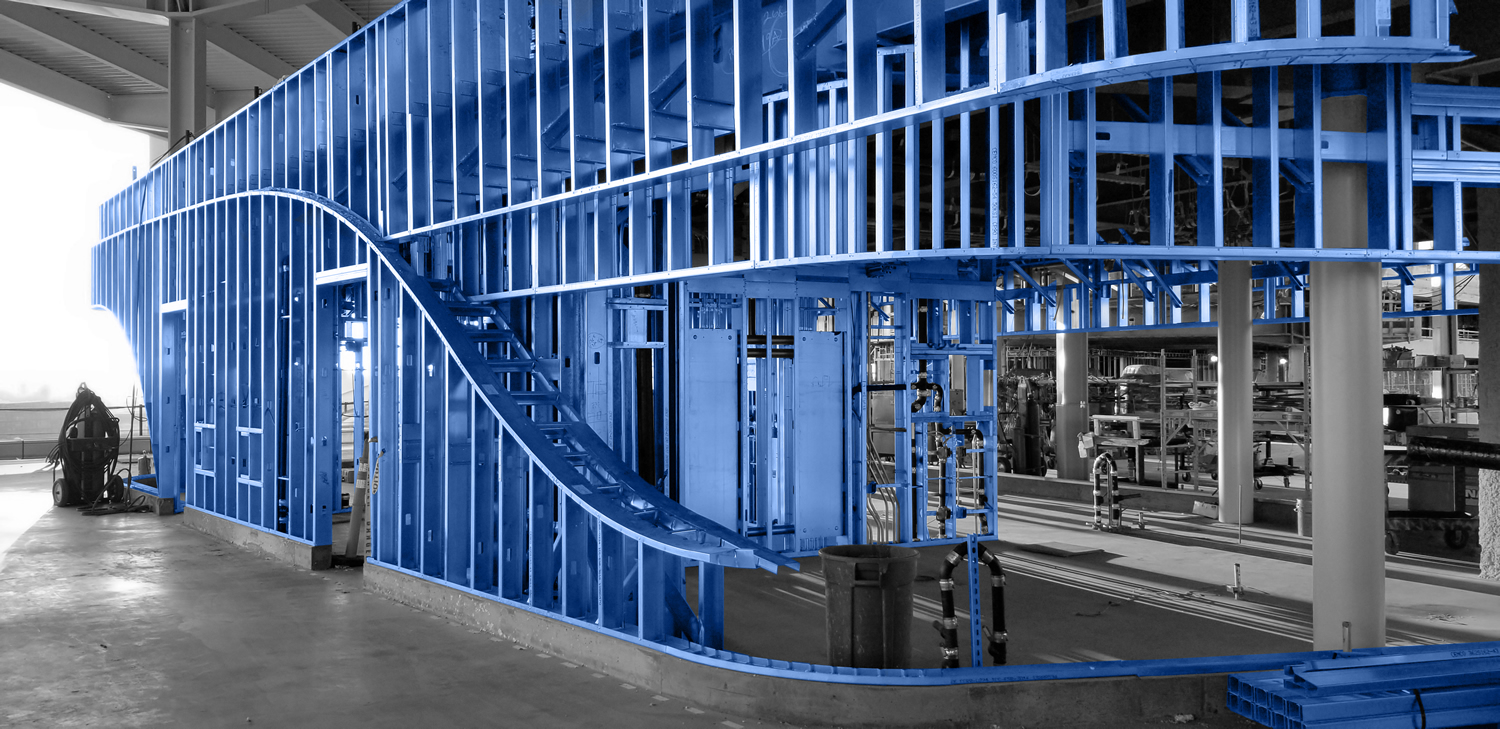

STRUCTURAL EVOLUTION LLC – SOFI STADIUM POD BUILDINGS

INGLEWOOD, CALIFORNIA

SoFi Stadium Pod Buildings SoFi Stadium Pod Buildings

1001 S. Stadium Drive

Inglewood, California 90301

Completed: September 8, 2020

Construction Cost: $5-6 billion

Owner: Kroenke Sports & Entertainment

Architect of Record: HKS Architects, Inc.

Engineer of Record for Structural Work: Rafael Sabelli, P.E., S.E., Walter P. Moore and Associates

Cold-Formed Steel Specialty Engineers: Wade Harrell, P.E. and John Lyons, P.E.,Structural Evolution LLC

Cold-Formed Steel Specialty Contractors: Robert Tripp and Kevin Hogan, Nevell Group/Martin Brothers

Award Entry Submitted by: John Lyons, P.E., Structural Evolution LLC.

Project Background

SoFi Stadium is a sports and entertainment venue which serves as home to both the Los Angeles Rams and the Los Angeles Chargers. This 70,240-seat facility features dramatic sweeping curves, eight concourse levels, and a fixed one million-square-foot structural steel framed roof supporting translucent ETFE panels. The structure includes 60,000 tons of structural steel. The scale and complexity of the structural steel tested the capacity of several steel fabricators in the U.S. and China.

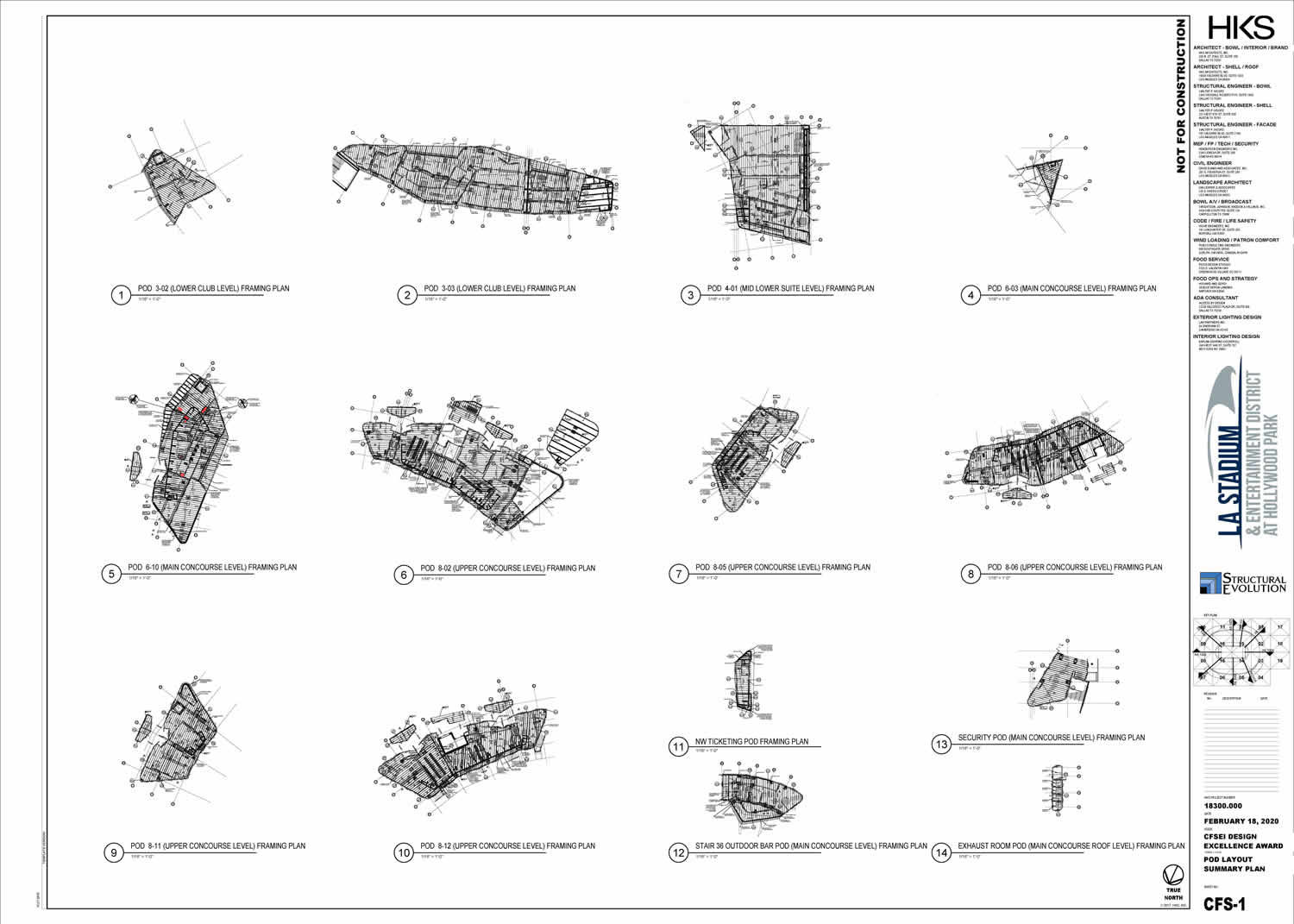

In 2017, during the design of the project, the engineer of record and the architect reached out to Structural Evolution for help. Within four of the concourse levels and on the building exterior, the architect planned a total of 14 “pod” structures. These pods are one-story buildings built within the larger open-air structure; they house space for concessions, restrooms, bars and ticketing.

The pod structures consist of curved and complex shapes, as shown on drawing CFS-1. By constructing these buildings out of cold-formed steel framing, another steel trade could be brought into the project, allowing structural steel erection to proceed more swiftly. Structural Evolution joined the design team, working closely with the engineer of record and the architect.

Design Challenges and Solutions

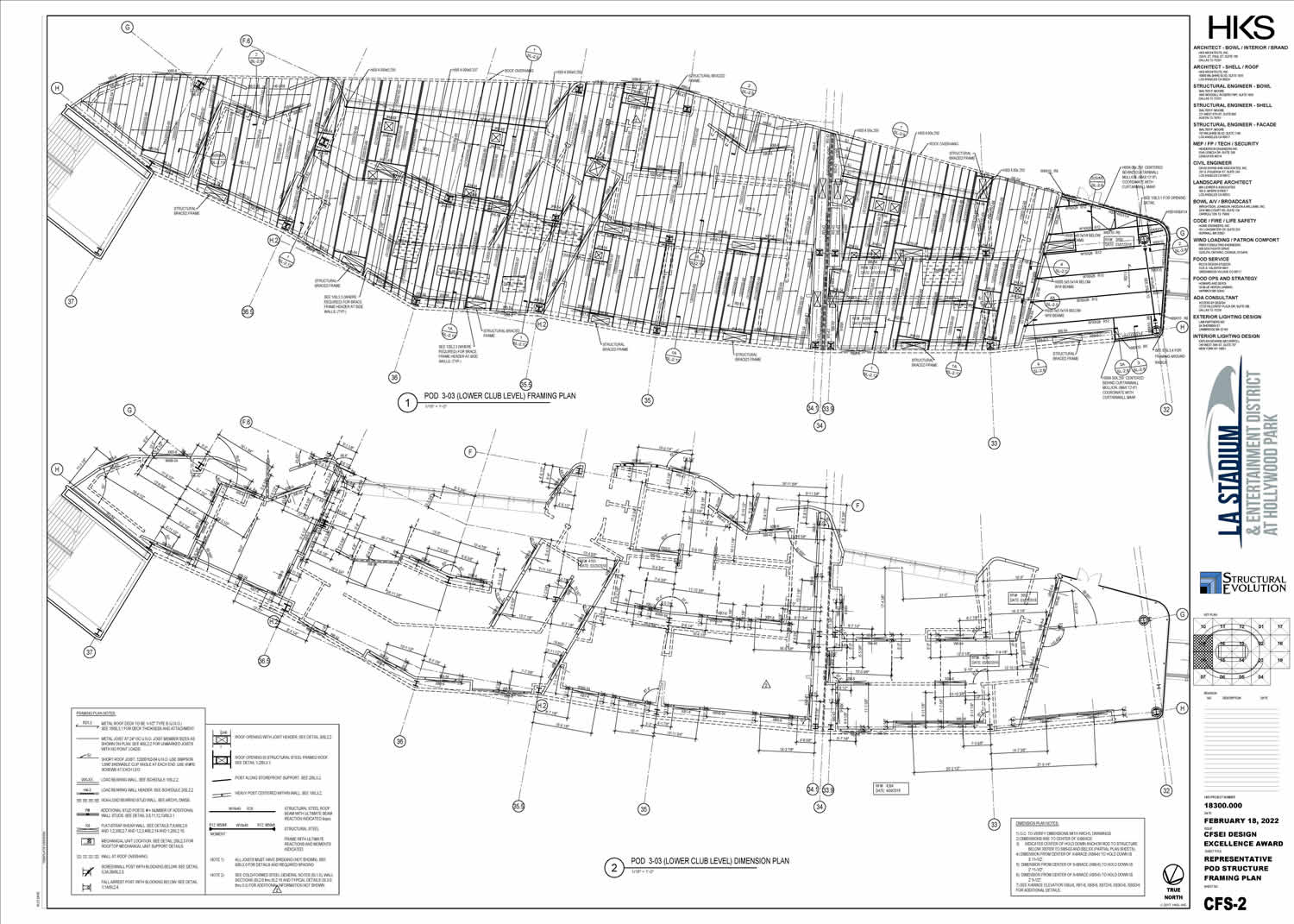

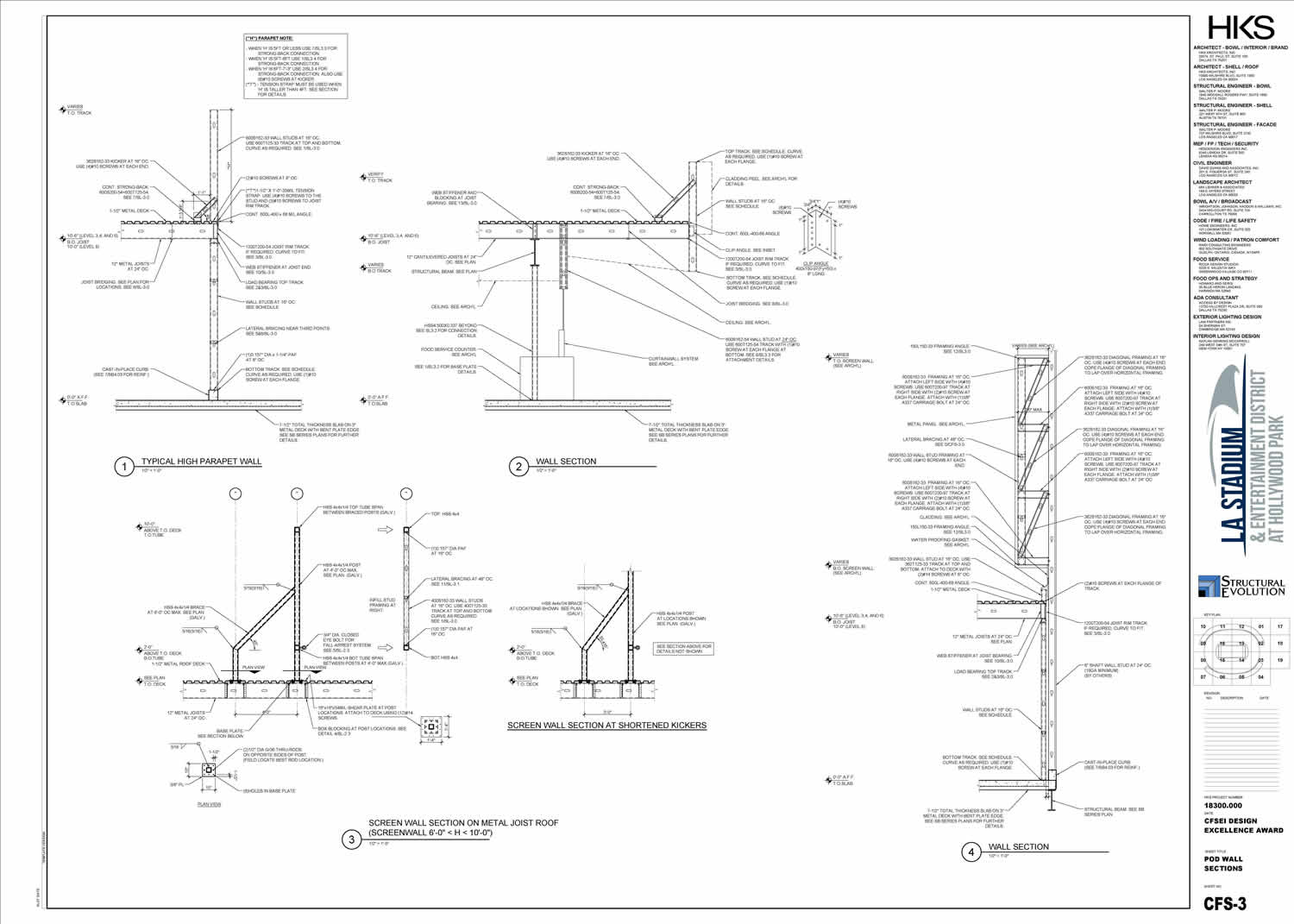

Initial meetings between Structural Evolution and the design team led to the development of a basic structural system for the pod buildings. The roof system needed to accommodate spans up to 30 feet and support rooftop air handling units, screen walls, and camera equipment. Load-bearing walls were often curved in plan view, meaning the roof member lengths were non-uniform. Based on this, the selected framing system consisted of metal roof deck on 12” cold-formed steel joists at 24”oc. Load-bearing wall studs consisted of 6” cold-formed steel studs at 16”oc with a segmented load-distribution top track. This track allowed the roof joists to fall at any position on the load-bearing wall. Flat strap X-braced shear walls provided lateral resistance. Refer to drawings CFS-2 and CFS-3 for typical plans and sections.

- Accelerated Design Schedule: After selecting the structural system, the architect began finalizing plans and sections for the pods. Upon completion of the architectural plans, Structural Evolution had a short four weeks to design the framing system for the 14 pod buildings. In preparation for this compressed schedule, we designed many elements ahead of time. We prepared tables of predesigned roof joists, joist headers, and wall openings based on spans under typical loading. We also designed a spreadsheet to allow rapid lateral analysis of the pod buildings which had numerous shear walls in many different non-parallel directions.

Once the final architectural plans arrived, the entire Structural Evolution engineering and detailing staff went to work. Each engineer was responsible for several pod buildings. Engineering efforts focused on unusual elements, since common elements were already designed. Lateral design was completed quickly, and we used typical shear wall designs on all buildings. Structural Evolution was able to meet the aggressive design schedule by selecting a simple, repetitive structural scheme--and by giving our staff the necessary tools to design the framing rapidly.

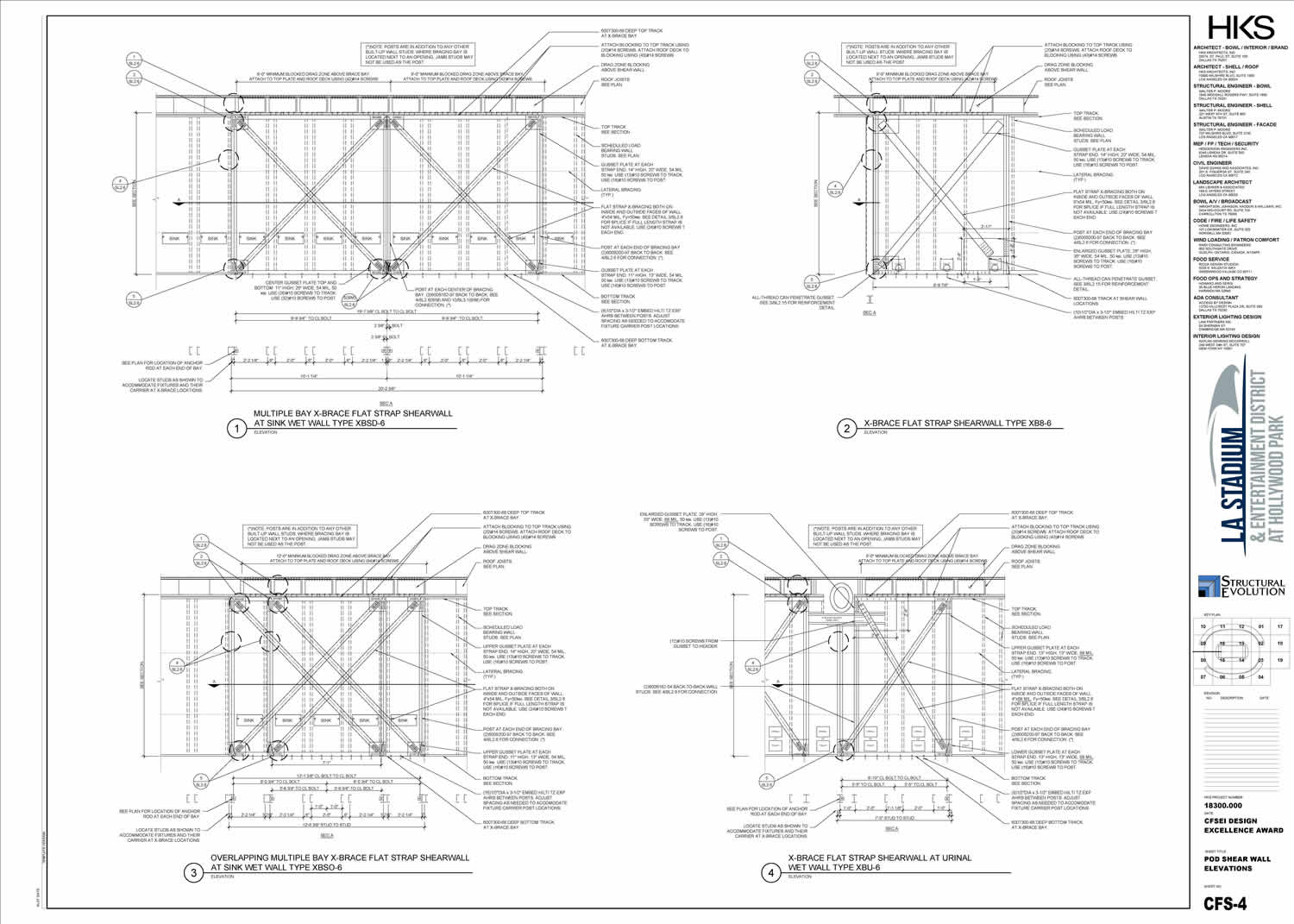

- Shear Wall Design: The San Andreas Fault lies just eight miles from the stadium; this presented an increased challenge for lateral design. A site-specific seismic study was provided, helping us to more accurately determine the design requirements. The shear walls consist of flat strap X-braces with gusset plates. (See drawing CFS-4 for shear wall details.) Blocking between joists transfers lateral load from the roof deck to the top of the shear wall. Shear wall hold-downs anchor directly to the structural steel frame below. Where lateral loading is high, we used double shear walls and woven shear walls (See details 1 and 3 on drawing CFS-4). To maximize floor space, we eliminated double walls at the restroom wet walls. Shear walls at the wet walls were carefully coordinated with plumbing fixtures for sinks, urinals and toilets (See details 1 through 4 on CFS-4). All X-brace hold-down locations were designated on plan view to help with the provision of structural steel beams for support (See plan 2/drawing CFS-2).

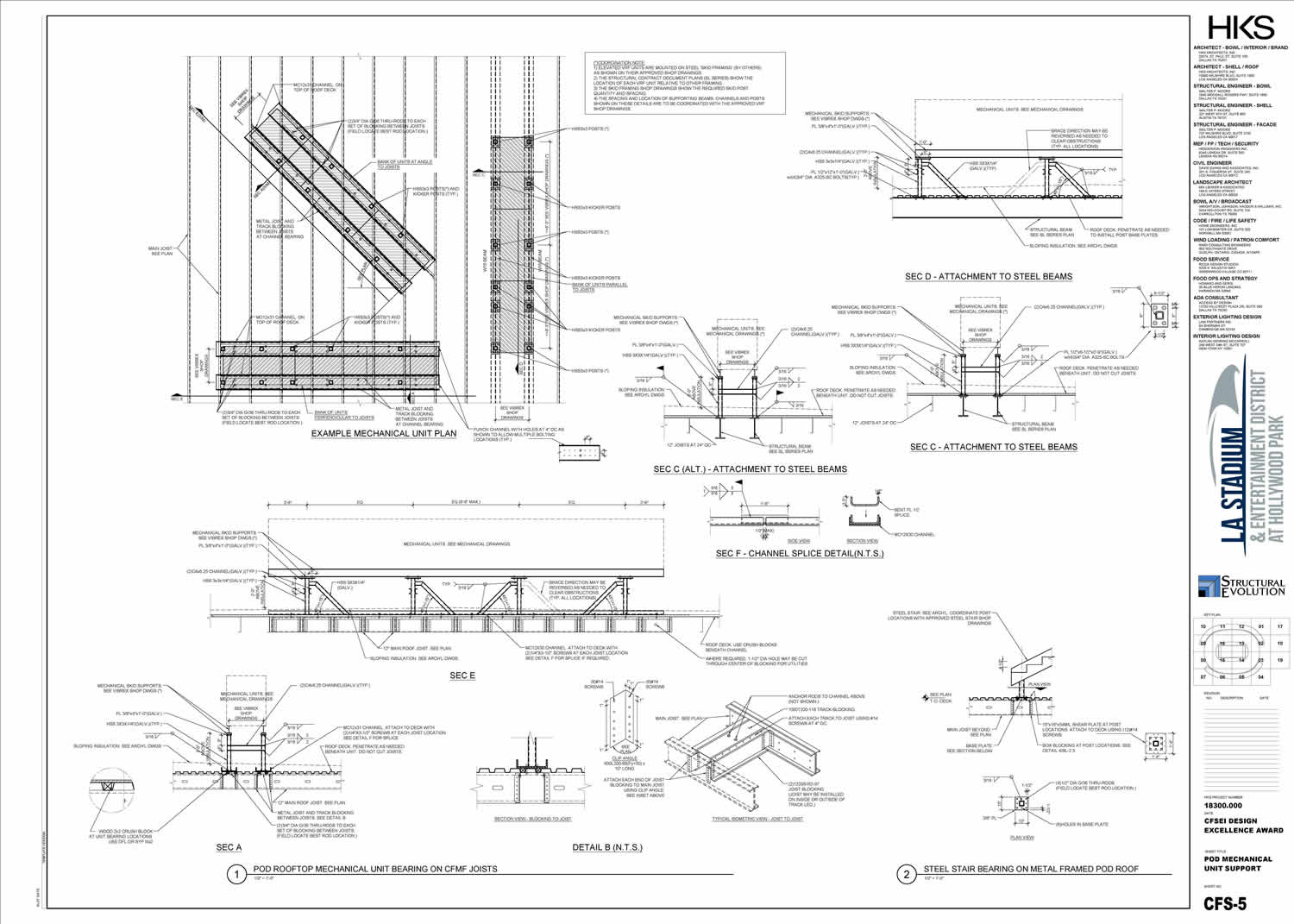

- Rooftop Mechanical Support: Each of the pod buildings holds rooftop mechanical units. In addition to the operating weight of the mechanical units, supports needed to carry substantial seismic lateral loads. The design of the mechanical supports needed to avoid large, concentrated loads which might easily exceed the capacity of a roof consisting of 12” cold-formed steel joists. To solve this problem, we designed the mounting of mechanical unit support steel to MC12x31 skids. (See detail 1/CFS-5, sections A, B, and E.) These skids distribute the loading from the rooftop units to multiple roof joists. Also, the skids are bolted to blocking between the joists to resist overturning seismic forces. Structural steel beams were still needed in some locations, but overall, the use of structural steel was kept to a minimum.

Summary

SoFi Stadium is an architectural and engineering marvel in many ways. The creative use of cold-formed steel framing on this project played an important role in its creation. By advancing the art of cold-formed steel framing design, Structural Evolution was proud to contribute to the success of the project.

|