2022 CFSEI DESIGN EXCELLENCE AWARD WINNERS

THIRD PLACE – RESIDENTIAL/HOSPITALITY

McCLURE – HUB II ON CAMPUS

GAINESVILLE, FLORIDA

Hub II on Campus

1258 NW 3rd Avenue

Gainesville, Florida 32601

Completed: 2021

Owner: CORE Spaces

Architect of Record: Antunavich Associates

Engineer of Record for Structural Work: Bill McNealy, P.E., McNealy Engineering

Cold-Formed Steel Specialty Engineer: Marcus Himmelberg, P.E., McClure

Cold-Formed Steel Panel Fabricator: Eisen Group LLC

Cold-Formed Steel Specialty Contractor: Bruce Schierding, Eisen Group LLC and Dusty Dahmer, Dahmer Contracting

Award Entry Submitted by: Lauren Gutknecht, McClure

Project Background

Located in central Gainesville, Florida, Hub II is a seven-story, 250,000-square-foot multi-use commercial and residential building. Six stories of cold-formed steel (CFS) over a one-story PT concrete podium make up Hub II. The CFS structure consists of a concrete floor over CFS joists and CFS wall panels.

Design Challenges and Solutions

Many design aspects of the CFS make this project unique.

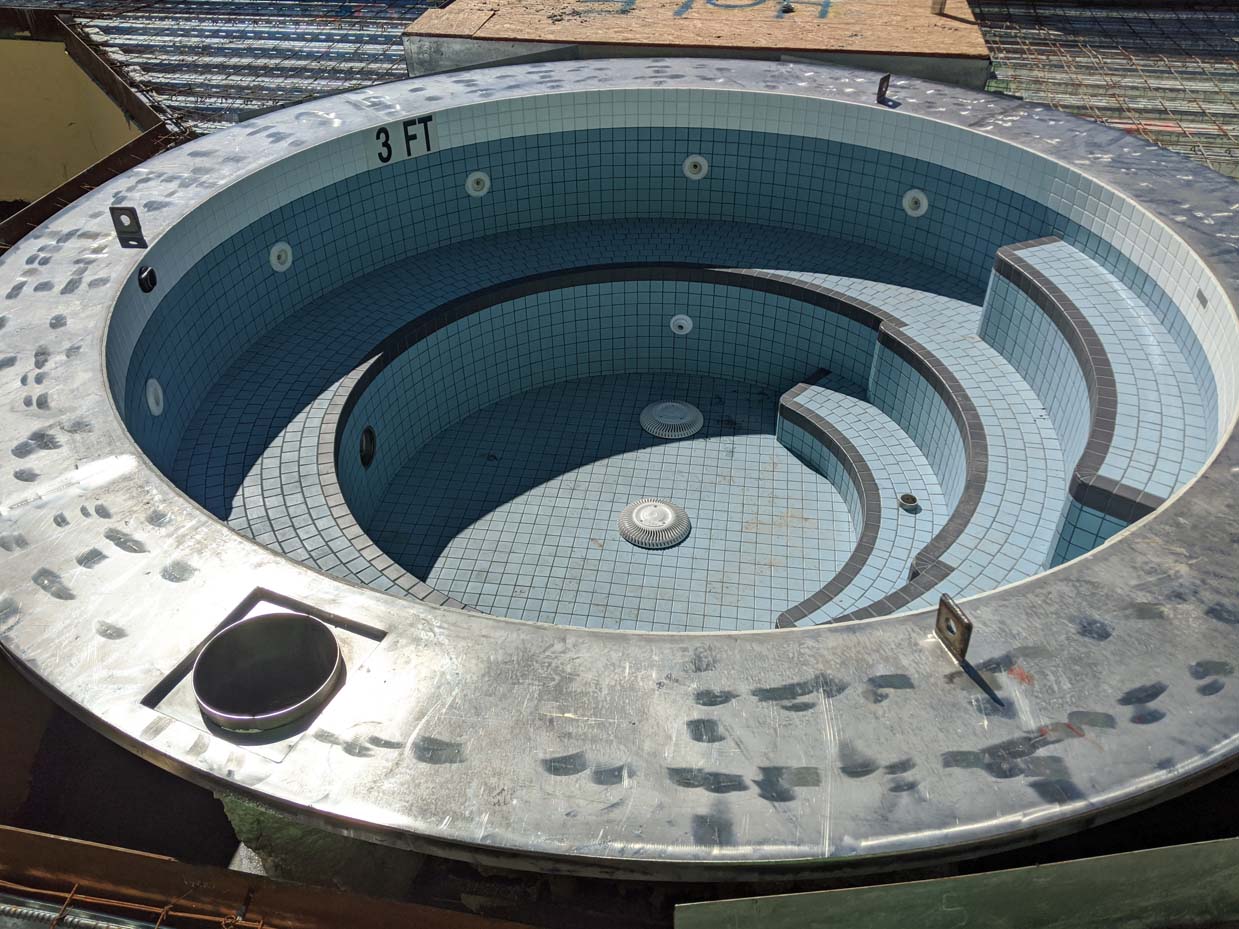

The first unique feature is the design and support of the rooftop pool. It is designed for and supported by the CFS structure rather than the typical concrete or red iron section of the building. Several considerations went into the support of the pool, including dynamic and seismic effects on the structure.

While McClure did not serve as the Engineer of Record (EOR), the design team quickly looked to McClure as the CFS experts to help work through the design components of the structure. Ultimately, to bring the loads down in the CFS panels, the idea to turn the joists under the pool was utilized to reduce the spans and decrease the loads on the panels in that section of the building. The process was further complicated by other pool and MEP requirements that had to be managed after the structure was already under construction. The lack of information provided by the pool manufacturer required several field fixes to allow for penetrations and other miscellaneous items to be added later. A well-thought-out design in the early stages with redundancy allowed these unknown features to be added without extensive fixes.

Another unique component of the project includes a panelized feature on the building. Due to the prominence of the structure in downtown Gainesville, a large feature and sign were desired by the owner and architect. To decrease the schedule and fieldwork, unique details were designed to support the feature in the panel system. The feature cantilevered as much as six feet from the face of the building, and vertical CFS trusses were utilized within the wall panels. The challenge was to create a truss that could be hoisted and attached from within the building while avoiding labor from the exterior on lifts. The McClure design team created a solution up to the task.

A third major design challenge was incorporating concrete shear walls using CFS formwork. McClure was vital in developing a panelized CFS system used for forming concrete walls and, in this case, shear walls as part of the lateral system. While McClure did not serve as the EOR on the job, the team looked to McClure to design the lateral components of the structure. The CFS form walls were used on each level to create shear walls up the building. There were very few hiccups with the process, leaving the contractors and owner very satisfied with the result. This task was also highlighted by the adjacent Hub I project.

As the CFS Specialty Engineer, McClure became the face of the design team and took on the role of a typical EOR throughout the project. McClure designed numerous elements throughout the project’s life span, including red iron and concrete vertical and lateral elements well beyond the typical day in and day out requirements of the average CFS project.

|