2016 CFSEI DESIGN EXCELLENCE

AWARD WINNERS

FIRST PLACE

BASE DESIGN GROUP, INC. – MEDITECH FOXBOROUGH OFFICE AND CONFERENCE CENTER

FOXBOROUGH, MA

Meditech Foxborough Office and Conference Center

1 Constitution Way

Foxborough, MA 02035

Completed: June 2015

Construction Cost: $35 million

Owner: MEDITECH

Architect of Record: Payette Associates Inc.

Engineer of Record for Structural Work: Goldstein-Milano LLC

Cold-Formed Steel Specialty Engineer: Base Design Group, Inc.

Cold-Formed Steel Specialty Contractor: Commercial Drywall & Construction Co. Inc.

Award Entry Submitted by: Nate Bacon, P.E., Base Design Group, Inc.

Project Summary:

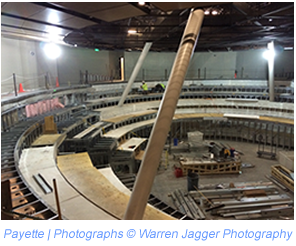

Meditech Foxborough Office and Conference Center is a four‐story structure located in Foxborough, Massachusetts that is home to MEDITECH. The project scope was a complete renovation of an existing structure that had not been occupied in years. The intent was to accommodate a new office space and conference center that included an auditorium and banquet hall for new product introduction, training sessions and other corporate gatherings. The renovation included the significant removal of an existing elevated concrete floor slab and existing steel columns to make way for a new two‐story, 568‐seat auditorium with a center stage area. The auditorium was to be constructed using cold‐formed steel framing as the primary structural system.

Meditech Foxborough Office and Conference Center is a four‐story structure located in Foxborough, Massachusetts that is home to MEDITECH. The project scope was a complete renovation of an existing structure that had not been occupied in years. The intent was to accommodate a new office space and conference center that included an auditorium and banquet hall for new product introduction, training sessions and other corporate gatherings. The renovation included the significant removal of an existing elevated concrete floor slab and existing steel columns to make way for a new two‐story, 568‐seat auditorium with a center stage area. The auditorium was to be constructed using cold‐formed steel framing as the primary structural system.

The design for the auditorium was unique because of its elliptical shape; the integration of five separate plenum zones beneath the seating surface; the presence of several rooms built into the underside of the auditorium seating; and the precise coordination between the framing members and the theater seating units, which functioned to facilitate air flow from the plenum zones into the auditorium space through each pedestal.

Once the existing structure was modified to create the necessary space for auditorium construction, Base Design Group, Inc. was brought onto the team to collaborate directly with Payette Associates Inc. and the contractors to help blend the desired structural system with the owner’s end use requirements and intricate MEP (mechanical, electrical and plumbing services) demands. Elevated concrete slabs on cold‐formed steel joists and bearing walls were introduced to create the necessary space and rating separation for the rooms beneath the auditorium. Cold‐formed steel joists on cold‐formed steel bearing walls were used to create the auditorium’s center stage, entry ramp, stairs and all seating tiers.

Once the existing structure was modified to create the necessary space for auditorium construction, Base Design Group, Inc. was brought onto the team to collaborate directly with Payette Associates Inc. and the contractors to help blend the desired structural system with the owner’s end use requirements and intricate MEP (mechanical, electrical and plumbing services) demands. Elevated concrete slabs on cold‐formed steel joists and bearing walls were introduced to create the necessary space and rating separation for the rooms beneath the auditorium. Cold‐formed steel joists on cold‐formed steel bearing walls were used to create the auditorium’s center stage, entry ramp, stairs and all seating tiers.

MEP penetrations, vertical drops and horizontal chase runs were carefully planned throughout the framing assembly system to permit all plenum zones below the seating surface to maintain intended separation and function ability. Cold‐formed steel lateral stability bracing was positioned to avoid interferences while still providing adequate room below the auditorium seating to allow all MEP systems accessibility for servicing throughout the structure’s life cycle. Additionally, the layout of all horizontal joists required precise coordination with the theater seating pedestal layout to avoid airflow interference and notching of structural members. On‐site surveying was then employed to assist with executing the exact layout of all framing members and seating.

The project was an exemplary example of quality design and build teams working in close collaboration to provide solutions to complex construction challenges using cold‐formed steel framing. This ultimately led to a smooth construction process and a successful project for all companies involved.

Download Case Study