2023 CFSEI DESIGN EXCELLENCE AWARD WINNERS

NON-BUILDING APPLICATION – FIRST PLACE

SALAS O'BRIEN – SOUTHWEST DOWNTOWN PEDESTRIAN BRIDGE

COLORADO SPRINGS, COLORADO

Southwest Downtown Pedestrian Bridge Southwest Downtown Pedestrian Bridge

W. Vermijo Avenue & S. Sierra Madre Street

Colorado Springs, CO 80903

Completion Date: July 2021

Completion Date: $20 million

Owner: City of Colorado Springs, Colorado

Architect of Record: Andrew G. Nielsen, Diller Scofidio+Renfro LLC

Engineer of Record for Structural Work: Jerry L. Brock, Arup North America, LTD

Cold-Formed Steel Specialty Engineer: Russ Leffler, Salas O’Brien

Cold-Formed Steel Specialty Contractor: Kyle Montague, Spacecon

Award Entry Submitted by: Ryan Nelson, Salas O’Brien

Project Background

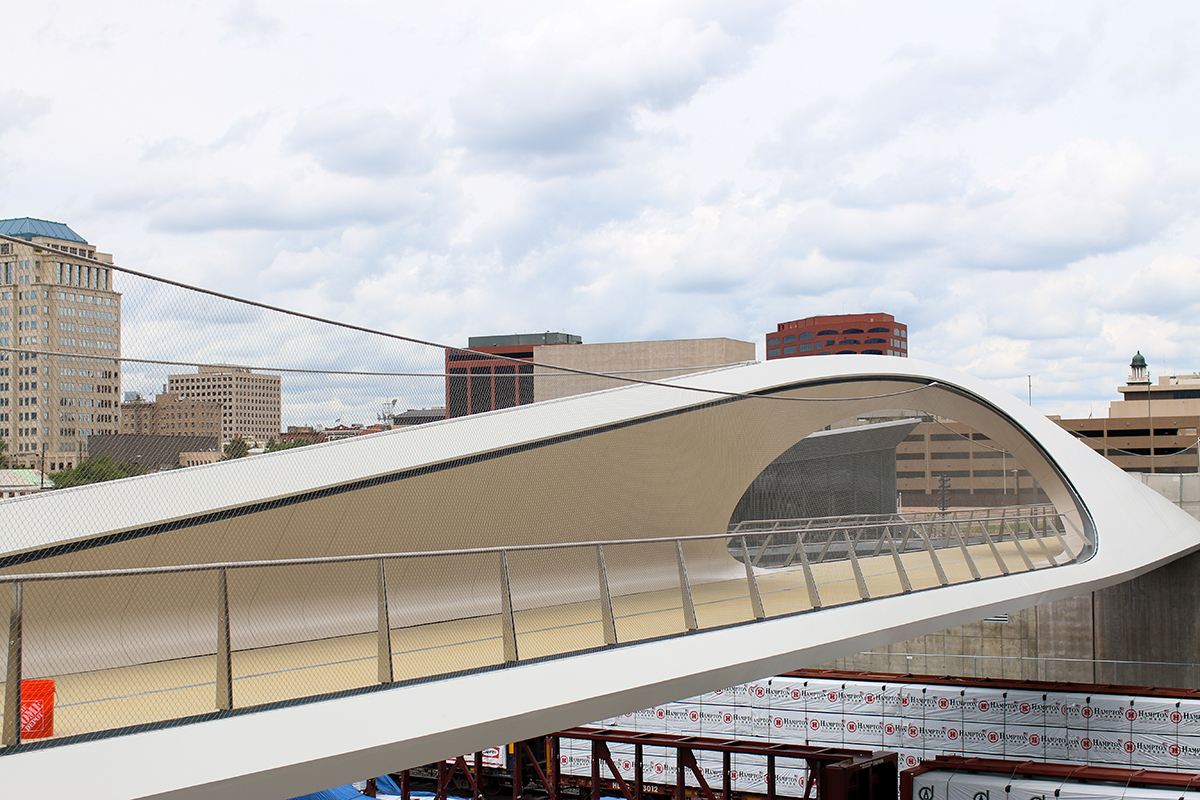

The “bridge of the future” is a 250-foot-long, 550-ton pedestrian bridge that connects the U.S. Olympic and Paralympic Museum with America the Beautiful Park. The bridge was fabricated in Houston, Texas in six separate sections and transported to Colorado Springs, Colorado to be constructed. This unique bridge is a hybrid steel structure combing an arch and a truss into two interlocking, twisting loops to form an oculus in the middle span that opens up to gorgeous views of Pikes Peak and downtown Colorado Springs. The “bridge of the future” is a 250-foot-long, 550-ton pedestrian bridge that connects the U.S. Olympic and Paralympic Museum with America the Beautiful Park. The bridge was fabricated in Houston, Texas in six separate sections and transported to Colorado Springs, Colorado to be constructed. This unique bridge is a hybrid steel structure combing an arch and a truss into two interlocking, twisting loops to form an oculus in the middle span that opens up to gorgeous views of Pikes Peak and downtown Colorado Springs.

Design Challenges and Solutions

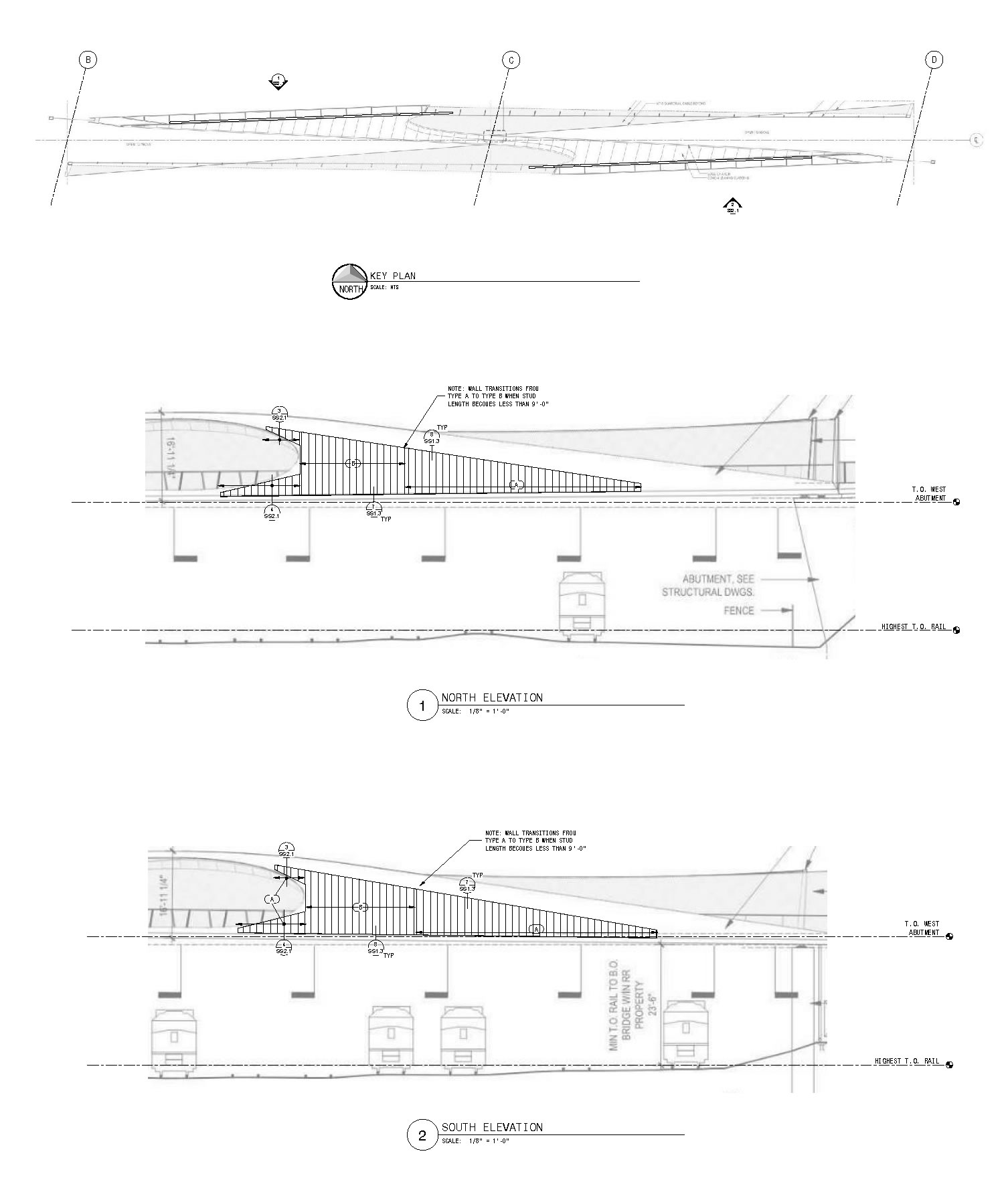

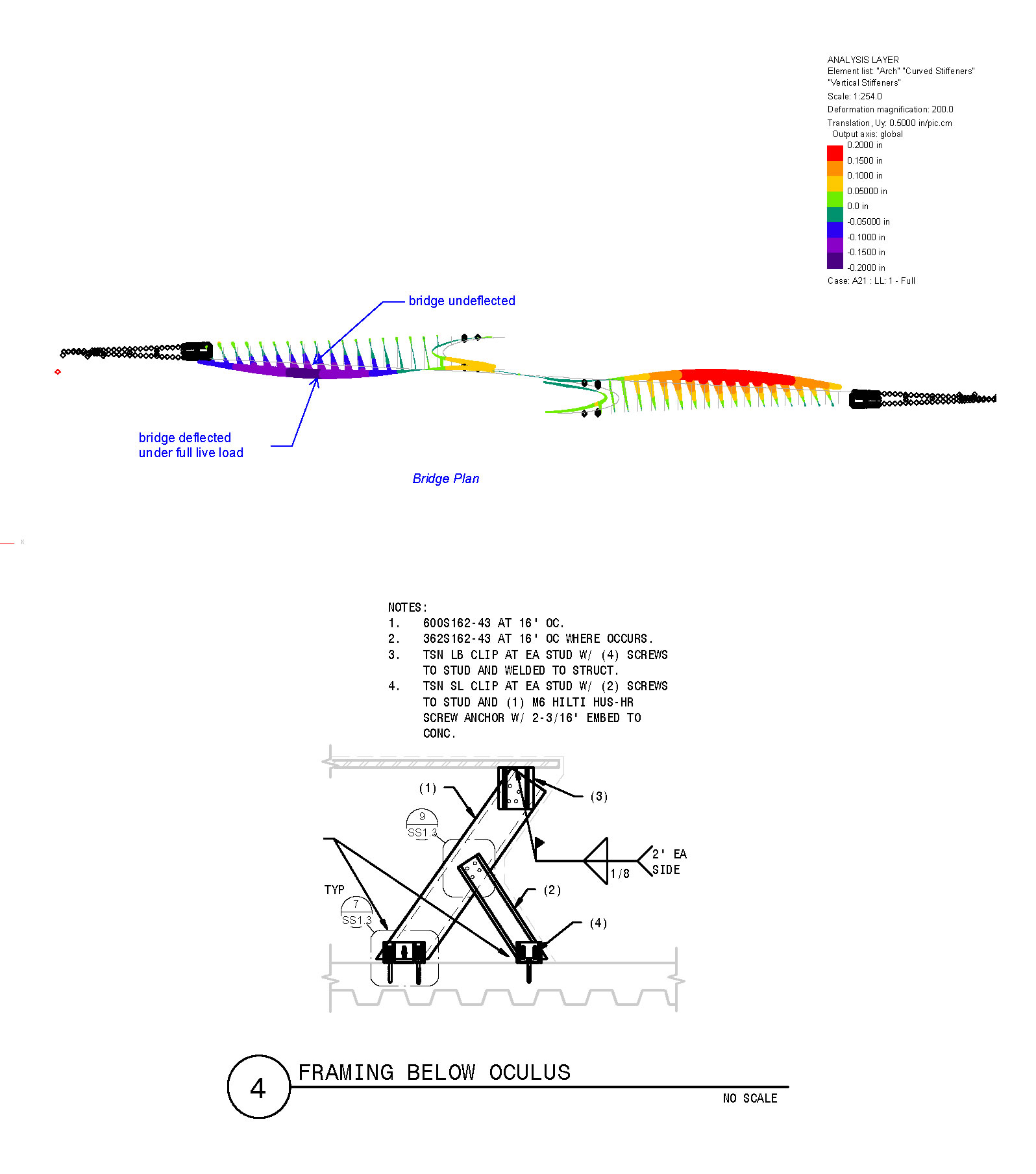

We were tasked with designing the 5400 cold-formed metal framing supporting the canted wall panels that wrapped the inside of the twisting oculus. The cold-formed steel (CFS) framing gradually curved and varied in height on each end, above and below the oculus. The biggest challenge presented by the CFS design was dealing with the three-dimensional and rotational movement of the steel structure as it induced thermal, wind, seismic, and live loads. To accommodate the complex movements in the bridge superstructure, each stud was rigidly fastened to the varying upper steel structure while the base was fastened to the concrete bridge with SL clips. The base connection only used two screws to the SL clips so that the connection could handle the rotational demands along with the vertical movement in the bridge. We were tasked with designing the 5400 cold-formed metal framing supporting the canted wall panels that wrapped the inside of the twisting oculus. The cold-formed steel (CFS) framing gradually curved and varied in height on each end, above and below the oculus. The biggest challenge presented by the CFS design was dealing with the three-dimensional and rotational movement of the steel structure as it induced thermal, wind, seismic, and live loads. To accommodate the complex movements in the bridge superstructure, each stud was rigidly fastened to the varying upper steel structure while the base was fastened to the concrete bridge with SL clips. The base connection only used two screws to the SL clips so that the connection could handle the rotational demands along with the vertical movement in the bridge.

It took several iterations and meetings with the engineer of record, panel manufacturer and contractor to secure the final design. Each element required an allowable tolerance of movement so that the panels could achieve their flawless smooth appearance. The completed project is impressive and appreciated by visitors. It took several iterations and meetings with the engineer of record, panel manufacturer and contractor to secure the final design. Each element required an allowable tolerance of movement so that the panels could achieve their flawless smooth appearance. The completed project is impressive and appreciated by visitors.

|