2017 CFSEI DESIGN EXCELLENCE AWARD WINNER

FIRST PLACE/COMMERCIAL

SHAFFER WILSON SARVER & GRAY, PC - MGM NATIONAL HARBOR, OXON HILL, MD

MGM National Harbor

MGM National Harbor

101 MGM National Avenue

Oxon Hill, MD 20745

Completed: December 8, 2016

Construction Cost: $1.4 billion

Owner: MGM Resorts International

Architect of Record: Smithgroup JJR

Engineer of Record for Structural Work: Cagley & Associates

Cold-Formed Steel Specialty Engineer: Shaffer Wilson Sarver & Gray, PC (SWSG, PC)

Cold-Formed Steel Specialty Contractor: Rick Nicolari, Project Manager - Component Assembly Systems, Inc.

Award Entry Submitted by: Theodore R. Welti, P.E., Division Manager - SWSG, PC and Akhil Jain, Structural Engineer - SWSG, PC

Project Summary:

Project Summary:

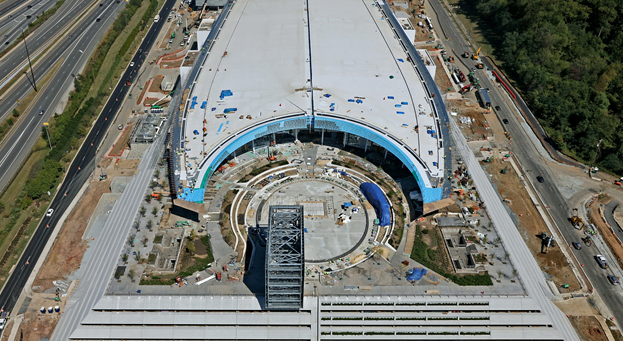

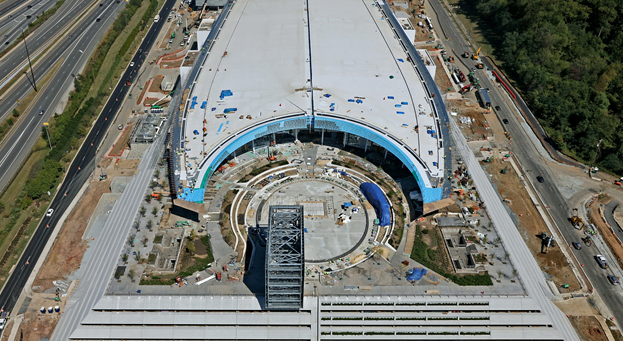

Located right outside of Washington DC, this casino and hotel complex was designed by architect HKS, Inc. The facility has a footprint of over 800,000-square-feet and consists of a casino, a theater with seating for 3,000 people, and a 23-story hotel. Both structural steel and concrete were used for the primary structural framing of the building.

Cold-formed steel was extensively used for external walls and also as a replacement for structural steel in some places. Additional cold-formed steel applications are included in the:

• Theater exterior wall framing

• Roof gutter along the perimeter of the casino building

• External wall and soffit framing along the perimeter of the casino building

• Hotel penthouse

• Unistrut ceiling support for Level 5

• Unistrut ceiling support for Level 2

• Theater interior walls

• Load bearing walls for artwork

• Casino and hotel canopy

• 30-to 40-foot-high exterior walls

• Ramps

• West Prow soffits and walls

Design Challenges

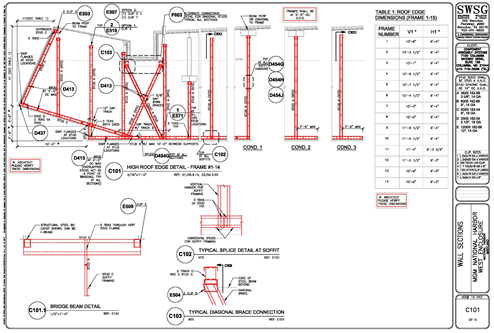

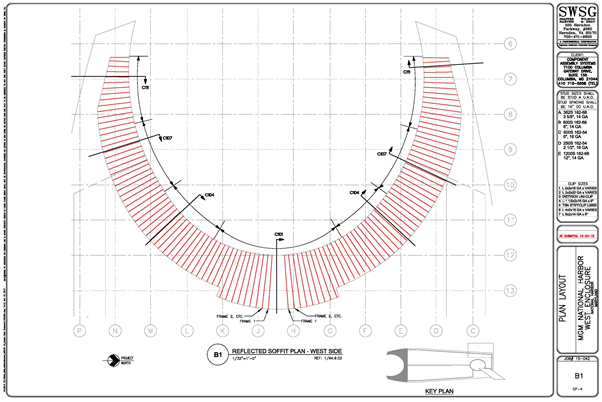

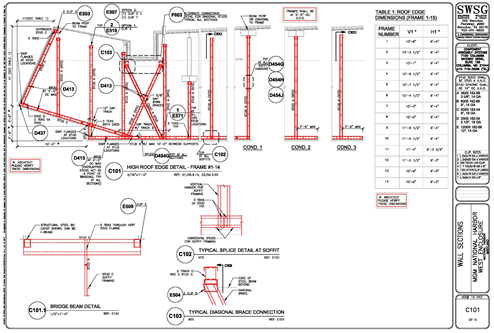

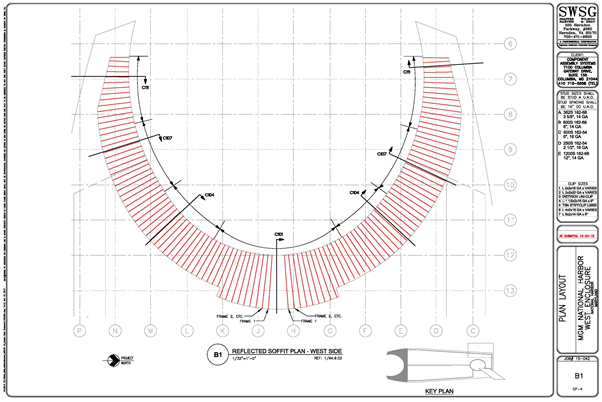

The most challenging design was the West Prow (or the West Casino Enclosure) which consists of 33’-0”-long unsupported soffit and a vertical face varying from 14 feet to 6 feet in height.

The complete framing had to be hung from structural steel beams. The load applied along the vertical and horizontal face was a challenge to design and construct. The lateral bracing for these frames were spaced at 5’-0” OC.

The curve along the claw made construction even more difficult. It was required that each individual frame, spaced at 5’-0” OC, be precisely measured from the 3D architectural drawings while calculating the alignment of cold-formed steel frames with respect to the structural steel beams. This process was needed to predict all the potential challenges that could arise due to the connection of cold-formed steel studs to structural support.

The complete process for the design of 60 different frames used in the West Prow involved extensive study of architectural and structural drawings, coordination with the contractor, Building Information Modeling (BIM), and multiple site visits. Each individual frame had to be supported laterally from a structural steel beam located between two cold-formed steel frames. This required the connection to be kept flexible in order to rotate almost 360 degrees.

Another challenge was the coordination required between the different disciplines. For example, while planning the Unistrut support framing for Level 5 and Level 2, it was important to consider all the obstructions between the Unistrut frames and the structural support slab above. According to Akhil Jain, SWSG’s structural engineer in charge of cold-formed steel framing design for the MGM project: “The BIM group from Component Assembly Systems, Inc. was a great help in sorting out the 3D model of the building and helping us better understand the feasibility of our design.” A thorough study of the architectural drawings, the MEP drawings, and the BIM model indicated the need to use two levels of “trapeze” to support the Unistrut ceilings.

Another great challenge was to find a manufactured clip that could be used with the bridging on 12” studs. Almost all clip manufacturers provide test values for their clips with up to 8” studs. For the 12” studs used in MGM Theater’s exterior walls, Simpson Strong-Tie agreed to get involved. Simpson Strong-Tie tested its MSUBH and LSSC clips for 12” stud bridging successfully and on time for use in the 45’-0”-tall theater walls of this project. Ted Welti, P.E., the cold-formed steel specialty engineer of record, also commended another supplier, The Steel Network, for its TSN VertiClip SLB slide clip, saying: “The clip had a very high capacity for wind suction loads perpendicular to and away from the theater wall surfaces. It was our clip of choice for the highest wind loads at corner zones.”

Visitors to Washington DC have a magnificent new landmark to explore, just a few miles from the traditional downtown attractions. MGM National Harbor demonstrates the design versatility and efficiency of cold-formed steel framing in a creative, dynamic and very large structure.

To see more photos, follow these steps:

- Visit http://www.swsgpc.com

- Click on “Plan Room.”

- Enter Username: MGM Photos and Password: see-more-MGM

- Click on links.

- Hit the “F5” button on your keyboard to refresh screen if necessary.

Download Case Study